High-Precision Casting & Advanced Manufacturing

Your Trusted Partner for Precision Casting Complex Component Manufacturing & Aerospace Equipment

About VastPCC

Founded in 2005, VastPCC has grown into a leading international manufacturer of critical high-end equipment parts. With decades of expertise, we specialize in Silica Sol Precision Casting, Precision Machining, and advanced Surface Treatment Technologies.

Our monthly production scale reaches 1.3 million units, supporting a diverse range of materials to meet complex industry demands. We proudly collaborate with prestigious partners such as the China Iron Steel Research Institute and Xi’an Aero Engine Corporation.

VastPCC is committed to innovation, quality, and reliability, positioning us at the forefront of the precision manufacturing industry.

About Us

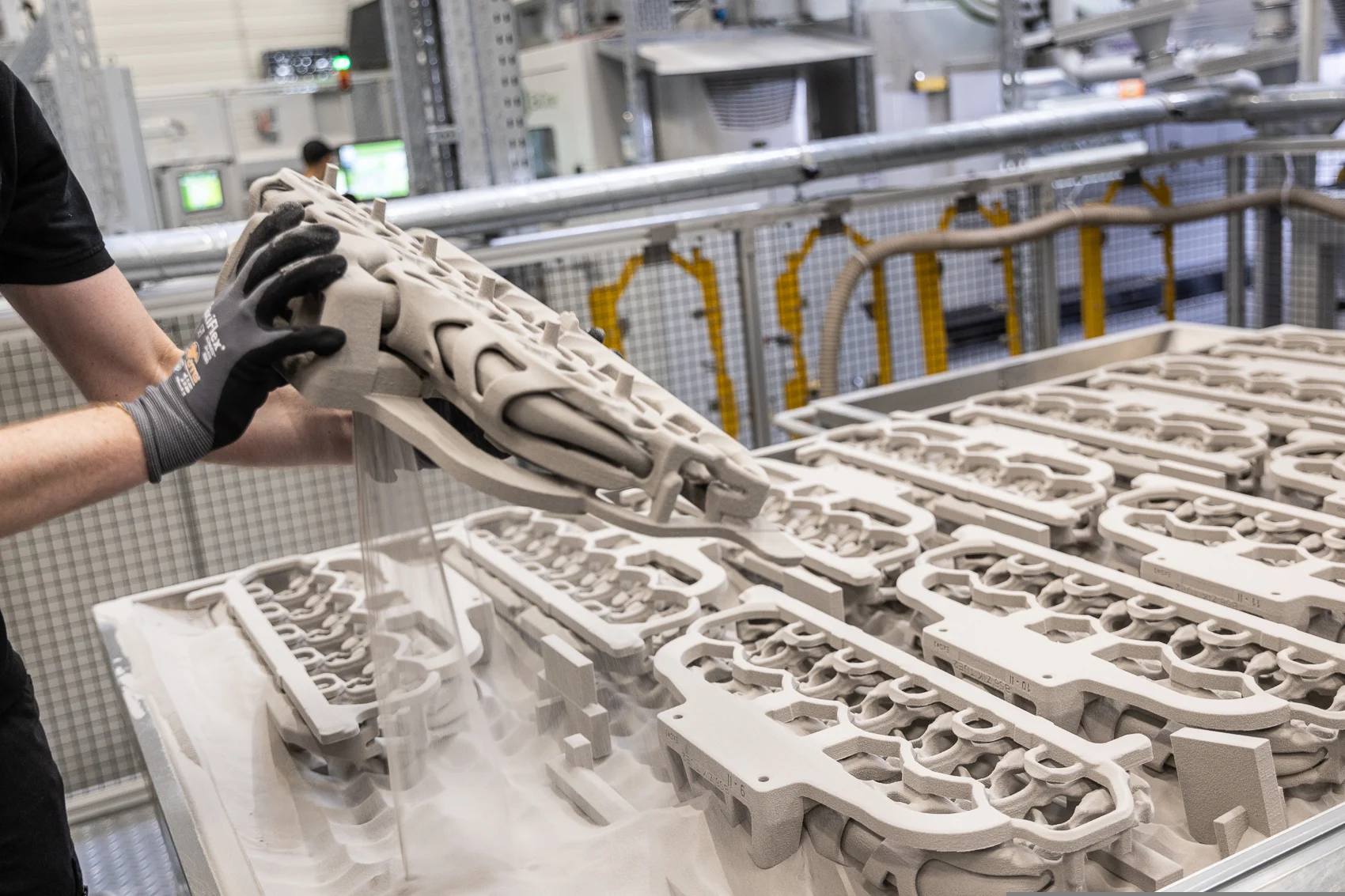

Silica Sol Precision Casting

Advanced silica sol casting techniques ensure superior dimensional accuracy and surface finish for complex components.

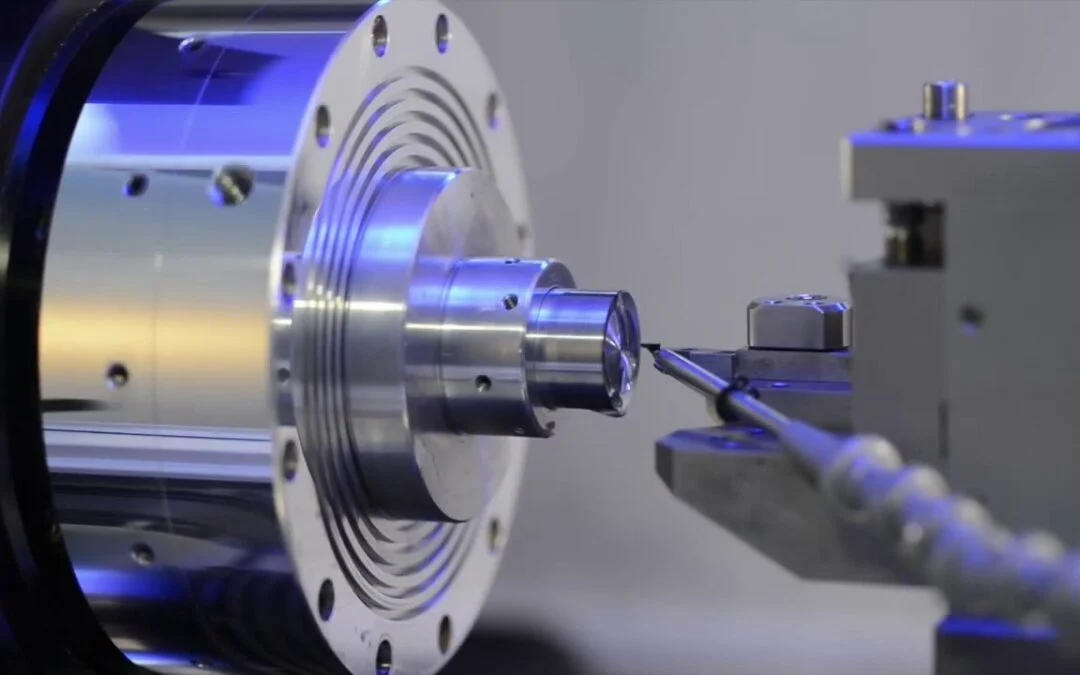

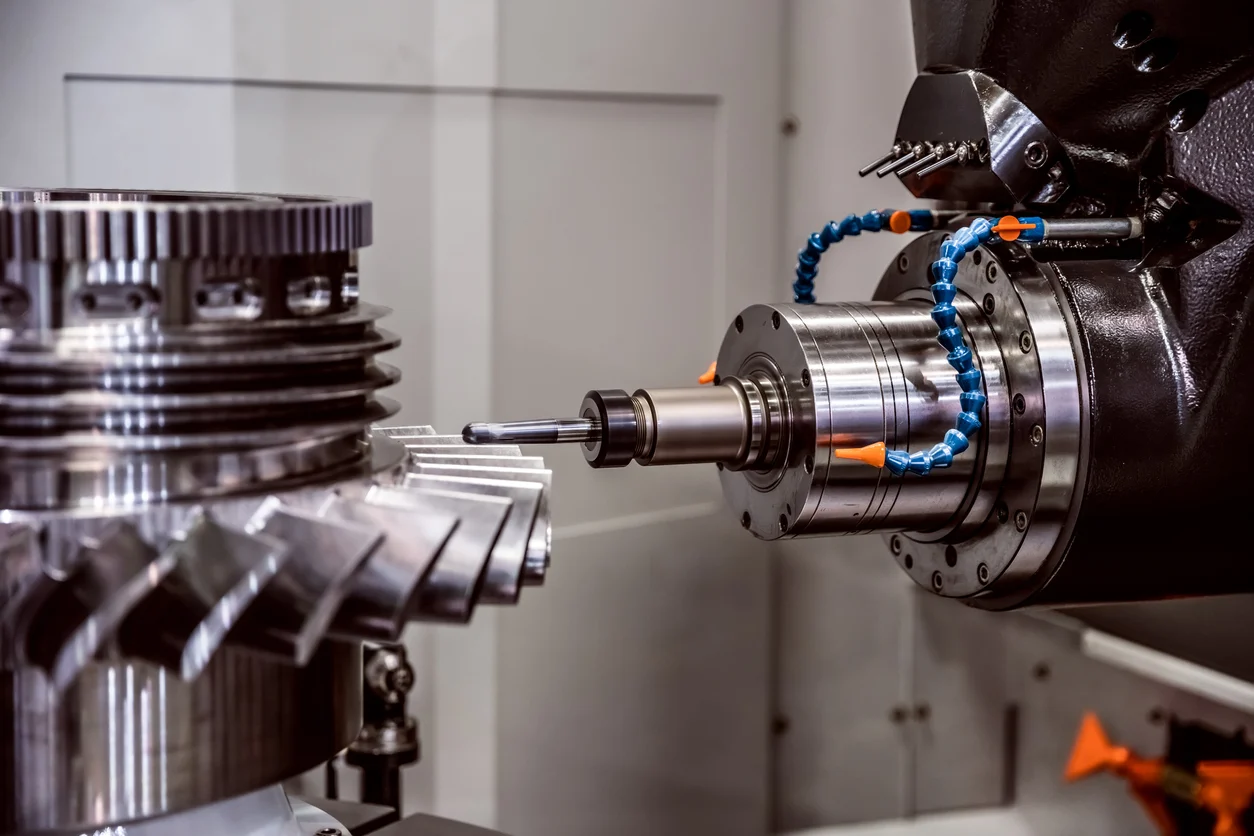

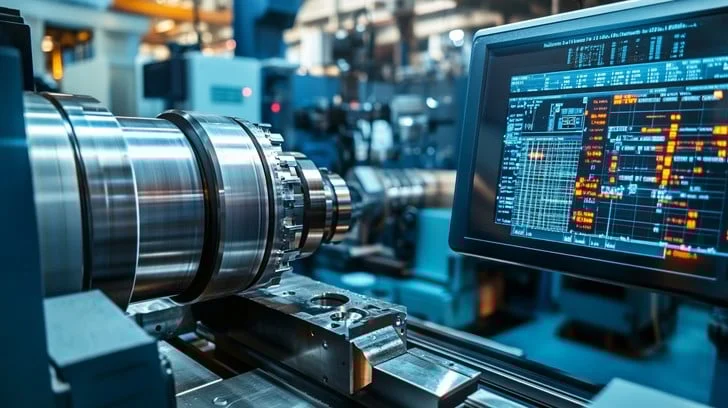

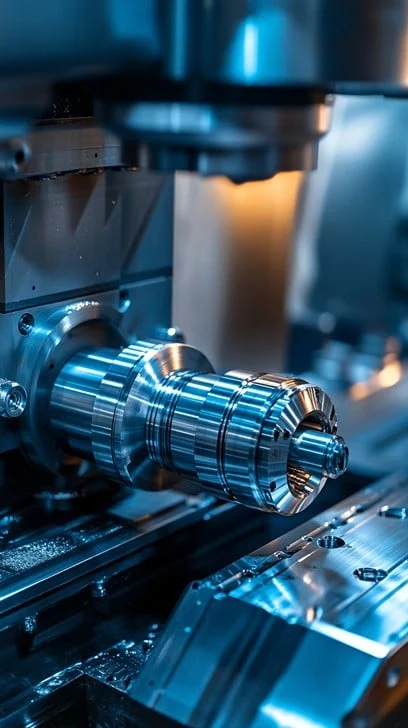

Precision Machining

State-of-the-art CNC machining capabilities deliver tight tolerances and consistent quality across diverse materials.

Surface Treatment Technologies

Innovative surface treatments enhance durability, corrosion resistance, and performance of critical parts.

Key Collaborations

VastPCC partners with industry leaders including the China Iron Steel Research Institute and Xi’an Aero Engine Corporation to drive technological advancements and meet the highest standards of quality and reliability.

Core Services and Technologies at VastPCC

Silica Sol Precision Casting

Utilizing advanced silica sol technology, VastPCC delivers high temperature alloy casting with exceptional precision. This method ensures complex structural part processing with superior dimensional accuracy and surface finish.

- High temperature alloy casting for aerospace & nuclear power

- Complex structural parts with tight tolerances

- Reduced defects and enhanced mechanical properties

Precision Machining Capabilities

Our precision machining services handle complex geometries with micron-level precision. VastPCC’s CNC and multi-axis machining centers enable processing of intricate aerospace and marine engineering components.

- Precision levels down to microns

- Complex structural part processing

- Optimized for aerospace gas turbines and marine parts

Surface Treatment Methods

VastPCC applies advanced surface enhancement techniques to improve wear resistance, corrosion protection, and thermal stability. These treatments are critical for components in nuclear power and aerospace sectors.

- Surface enhancement techniques for durability

- Industry relevance: aerospace, nuclear, marine engineering

- Benefits include extended service life and performance

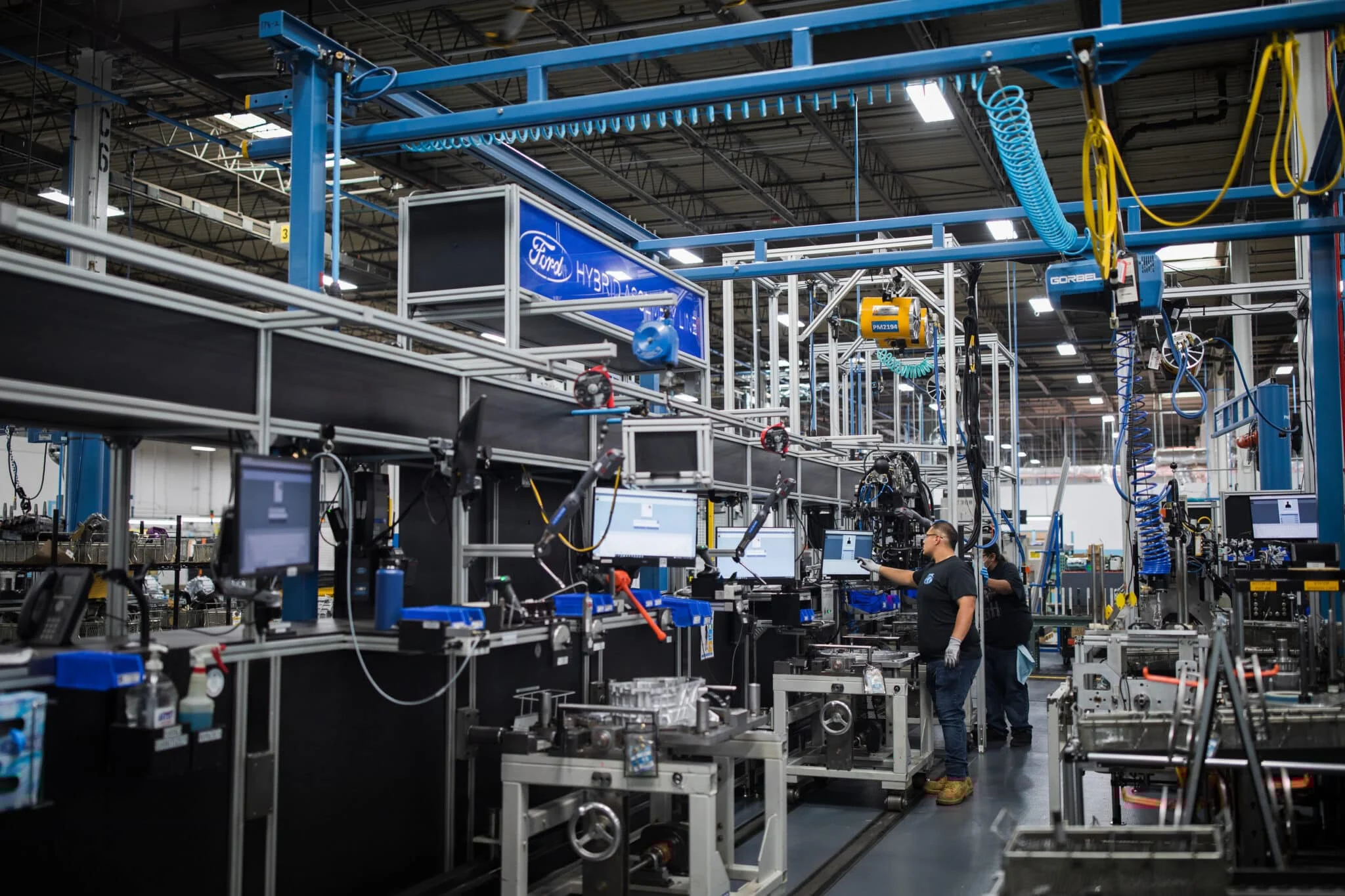

Manufacturing Facilities & Capacity

Major Production Bases

VastPCC operates state-of-the-art manufacturing facilities in Dongying and Qingdao, equipped with advanced machinery to support multi-material, high difficulty part mass production.

- Monthly capacity of 1.3 million parts ensuring stable output

- Innovative stress process technologies for enhanced precision

- Rigorous quality control standards for consistent excellence

- Advanced equipment tailored for complex manufacturing challenges

Manufacturing Capabilities & Quality Assurance

High Volume Capacity

Efficient processes enable production of over 1.3 million parts monthly, meeting large-scale demands without compromising quality.

Multi-Material Expertise

Specialized in handling diverse materials with precision, ensuring durability and performance for complex parts.

Rigorous Quality Control

Comprehensive inspection protocols and process innovations guarantee consistent, high-quality output.

Advanced Equipment for Stable Output

Our facilities feature cutting-edge machinery designed for high difficulty parts, ensuring stable and repeatable production cycles. This enables VastPCC to maintain leadership in precision manufacturing.

Continuous process innovations and strict adherence to quality standards empower us to deliver reliable components that meet the most demanding industry requirements.

VastPCC Product Showcase

Stainless Steel

Premium corrosion resistance and durability for demanding environments. Ideal for high-precision, complex geometries.

Heat Resistant Steel

Engineered for extreme temperatures, offering superior strength and longevity in thermal applications.

Carbon Steel Alloys

Balanced strength and machinability for versatile industrial applications with complex manufacturing challenges.

Non Ferrous Metals

Lightweight and corrosion-resistant metals tailored for precision components with demanding performance criteria.

Signature High-End Components

Showcasing our expertise in manufacturing complex geometries with precision and reliability. Overcome the toughest challenges with VastPCC’s advanced processes.

Explore ComponentsClients & Partners

VastPCC proudly collaborates with industry leaders across over 40 countries, driving international market expansion as a trusted supplier of high-end equipment. Our joint R&D initiatives and technological partnerships fuel innovation and excellence in manufacturing.

Main Industry Sectors

Serving aerospace, automotive, energy, and medical sectors with precision-engineered solutions tailored to each industry's unique demands.

Global Reach & Market Presence

Extensive partner network spanning 40+ countries, ensuring local expertise and seamless supply chain integration worldwide.

Joint R&D & Technological Partnerships

Collaborating on cutting-edge research and development projects to advance manufacturing technologies and product innovation.

Latest News & Industry Insights

Stay updated with VastPCC’s company announcements, precision casting innovations, and advanced manufacturing trends.

VastPCC Announces New Precision Casting Facility

Our latest plant expansion boosts production capacity and integrates cutting-edge casting technology to meet growing market demands.

Read More

Advanced CNC Machining Revolutionizes Automotive Remanufacturing

Explore how CNC advancements are improving precision, efficiency, and sustainability in automotive component remanufacturing.

Read More

Innovations in Investment Casting Materials

Discover the latest breakthroughs in silica sol binders enhancing precision and surface finish in investment casting processes.

Read More

Market Insights: Precision Casting Technology Trends

An in-depth analysis of emerging trends shaping the precision casting industry and their impact on manufacturing strategies.

Read More

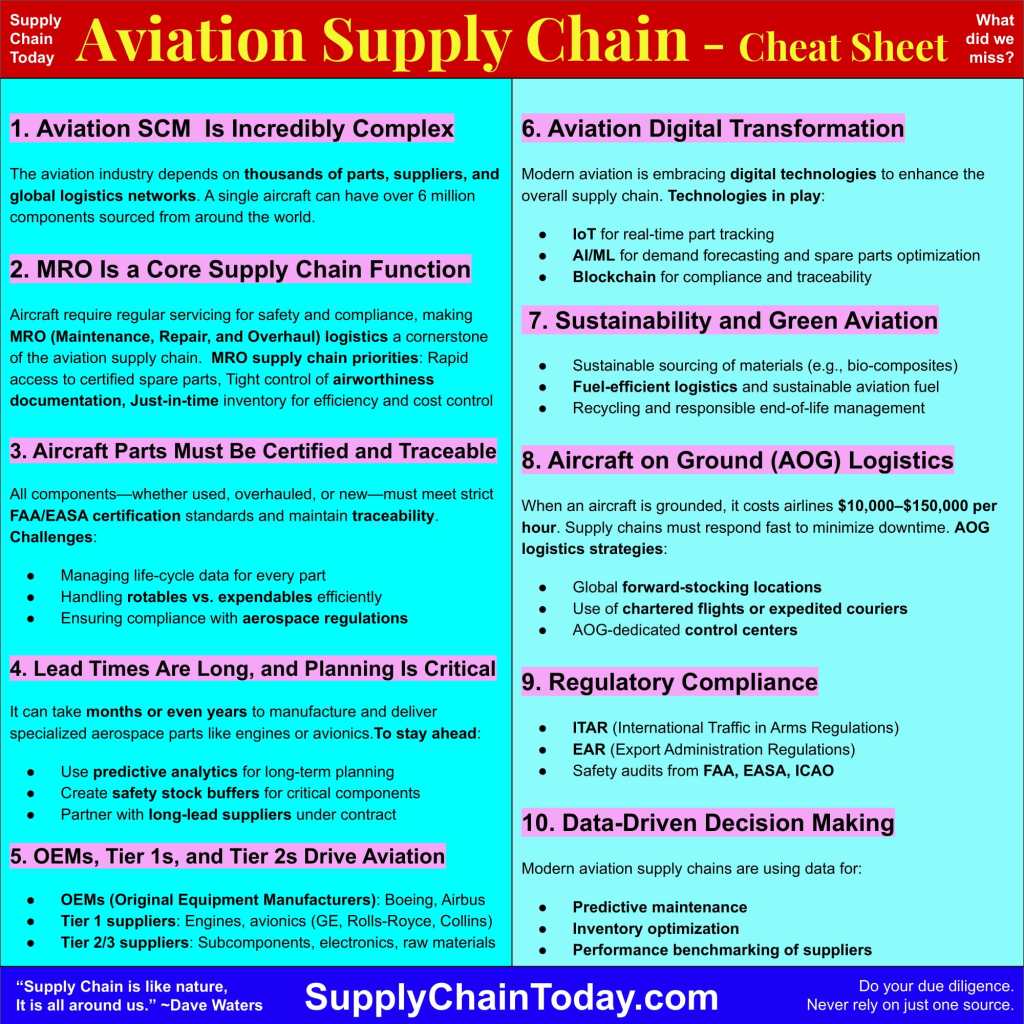

Industry Update: Supply Chain Innovations in Aviation

How advancements in supply chain management are driving efficiency and reliability in the aviation manufacturing sector.

Read MoreContact VastPCC

Get in Touch

We’re here to help with any questions or inquiries. Reach out to our professional customer service team for fast, reliable support.