Advanced Silica Sol Gel Casting & R&D

Highlighting VastPCC’s technical strength and innovation leadership in high definition silica sol gel precision casting.

Advanced Precision Casting Technology Overview

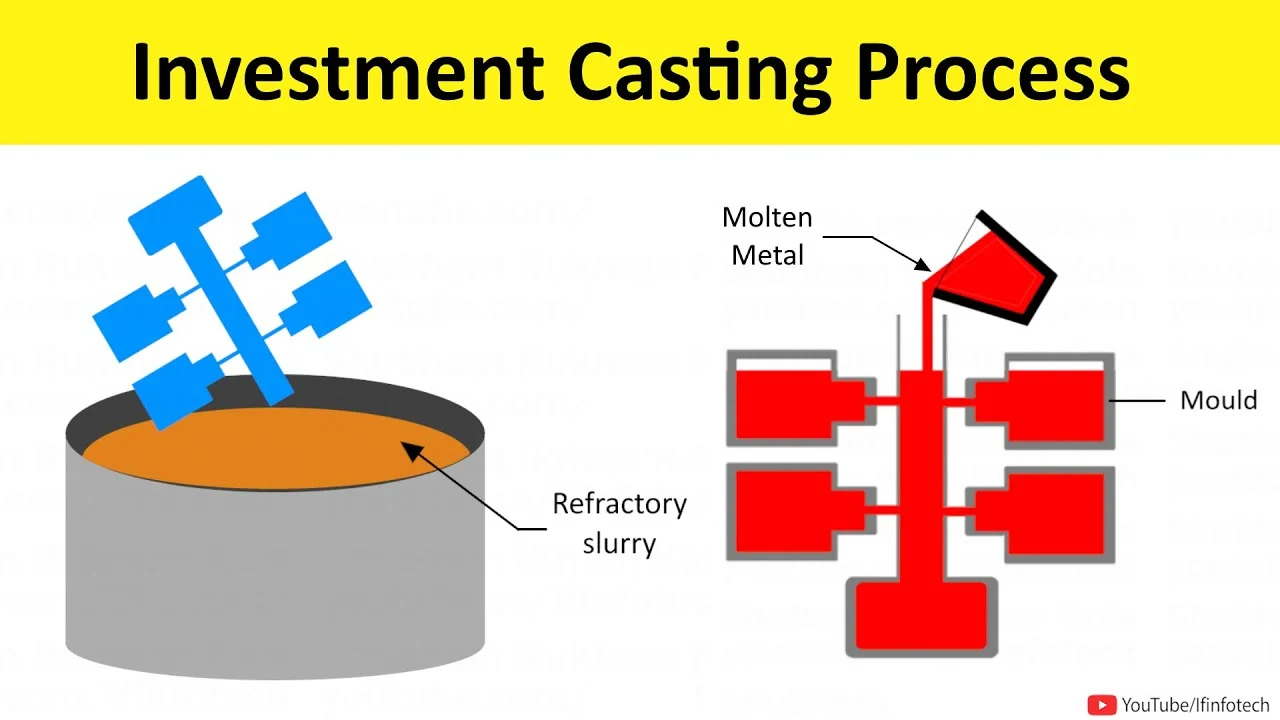

Silica Sol Gel Process Advantages

VastPCC’s proprietary silica sol gel precision casting technology offers superior dimensional accuracy, surface finish, and repeatability. This advanced process reduces defects and material waste by forming a uniform ceramic shell with excellent permeability and strength.

Key Technical Parameters

- Shell thickness control within ±0.05 mm

- High-temperature resistance up to 1600°C

- Optimized drying and curing cycles for minimal shrinkage

- Custom equipment ensuring consistent slurry application

Our proprietary equipment integrates seamlessly with the silica sol gel workflow, enabling natural embedding of casting technology keywords and ensuring process reliability.

Innovation & R&D Projects at VastPCC

Driving technological breakthroughs through flagship R&D initiatives including high temperature alloy development and complex structural manufacturing. Proudly collaborating with China Iron Steel Research Institute and Xi’an Aero Engine Corporation to push the boundaries of innovation.

Complex Structural Manufacturing

Utilizing advanced 3D fabrication techniques to create intricate structural components with unmatched precision and durability.

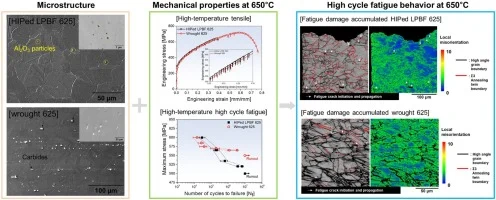

High Temperature Alloy Development

Developing cutting-edge alloys designed to withstand extreme temperatures, enhancing performance in aerospace and industrial applications.

Collaborative Case Studies

Partnership with China Iron Steel Research Institute

Joint research on innovative steel alloys has resulted in a 15% increase in thermal resistance and improved manufacturing efficiency.

- Advanced alloy composition analysis

- Enhanced durability testing protocols

- Scalable production methods

Innovation with Xi’an Aero Engine Corporation

Breakthroughs in aero engine component manufacturing have led to a 20% weight reduction while maintaining structural integrity.

- Complex geometry 3D printing

- Material performance optimization

- Real-time quality monitoring

Diverse Products & Extensive Applications

VastPCC specializes in high-end equipment components and precision machining, offering a wide range of products including stainless steel, heat resistant steel alloys, and non-ferrous metals. Our solutions serve critical sectors such as aerospace, gas turbines, nuclear power, and marine engineering.

Product Categories

- Stainless Steel

- Heat Resistant Steel Alloys

- Non-Ferrous Metals

Key Application Sectors

- Aerospace & Aircraft Engines

- Gas Turbines

- Nuclear Power

- Marine Engineering

Production & Export

With a robust monthly production capacity, VastPCC exports globally, meeting stringent quality standards and delivering precision components for high-end equipment worldwide.

Global Export Markets

VastPCC’s precision components reach customers worldwide, supporting industries that demand reliability and performance.

Precision Machining

Advanced machining techniques ensure every component meets exacting standards for high-end equipment.

Diverse Product Range

From stainless steel to heat resistant alloys, our products are engineered for durability and performance.

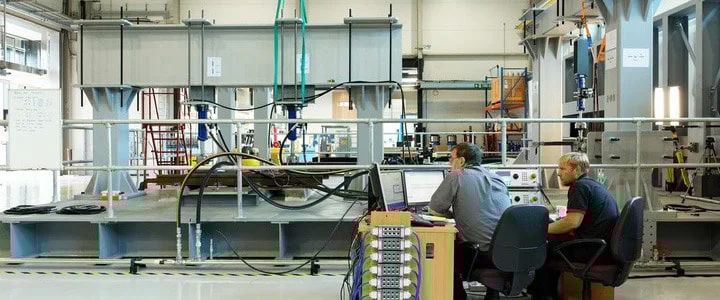

Modern Production Bases & Equipment Capabilities

Qingdao & Dongying Production Sites

VastPCC’s state-of-the-art production facilities in Qingdao and Dongying combine advanced automation with rigorous quality control systems. These sites are designed to maximize efficiency and maintain consistent product excellence.

Major Production Equipment & Automated Workflows

Our production lines feature cutting-edge machinery including precision casting, CNC machining, and automated assembly. Integrated workflows ensure seamless operations from raw material to finished product.

Production Scale & Quality Control

With large-scale manufacturing capacity, VastPCC emphasizes strict quality assurance protocols at every stage. Our comprehensive quality control system guarantees reliability and compliance with industry standards.

VastPCC: Industry Leading Brand Strength & Global Partnerships

Our History & Milestones

- 2005: Founded with a vision to innovate casting technology.

- 2012: Expanded operations internationally, entering key global markets.

- 2018: Launched proprietary GRX-810 casting process, revolutionizing precision.

- 2025: Recognized as a top global brand in advanced manufacturing solutions.

VastPCC Brand Value & Global Market Impact

VastPCC stands at the forefront of innovation, delivering unmatched quality and precision in casting technology. Our commitment to excellence and sustainable growth has earned us a trusted reputation across domestic and international markets, driving industry standards and empowering partners worldwide.

Professional Technical Support & Customer Service

Technical Consultation & Inquiry Process

Our expert team is ready to assist you with any technical questions or product inquiries. Reach out via phone or email to start your consultation, and we’ll guide you through tailored solutions to meet your needs.

After-Sales Support & Customer Training

We provide comprehensive after-sales maintenance and training to ensure you get the most from your purchase. Our support includes troubleshooting, regular maintenance, and hands-on training sessions.

Contact Us

Phone:+0086-0532-89069810 0086-13345064499 Email::postmaster@vast-cast.comAddress: No. 19 Jifa Longshan Road, Jimo Environmental Protection Industrial Park, Qingdao City

Contact SupportFrequently Asked Questions