Critical Solutions for Gas Turbine & Power Plant Components

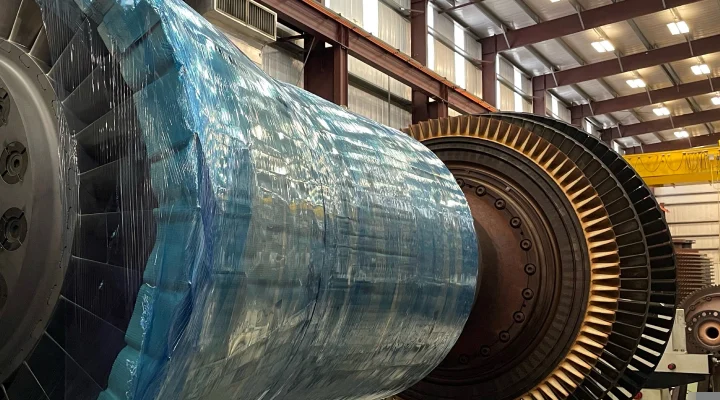

Premium High-Temperature Alloy Parts with Strict Quality Assurance to Empower Reliable Operation of Advanced Equipment

VastPCC Company & Business Overview

Founded on deep expertise in advanced metallurgy and manufacturing, VastPCC boasts robust production capacity specializing in high-temperature alloy components for gas turbines and power plants.

Our core business focuses on precision casting and surface treatment technologies, ensuring superior quality and performance in demanding industrial environments.

Core Competencies

- Independent R&D capabilities driving innovation

- Strategic partnerships with China Steel Research Institute and Xi’an Aero-Engine Corporation

- Strict compliance with rigorous industry quality standards

VastPCC Products & Technology

Product Categories

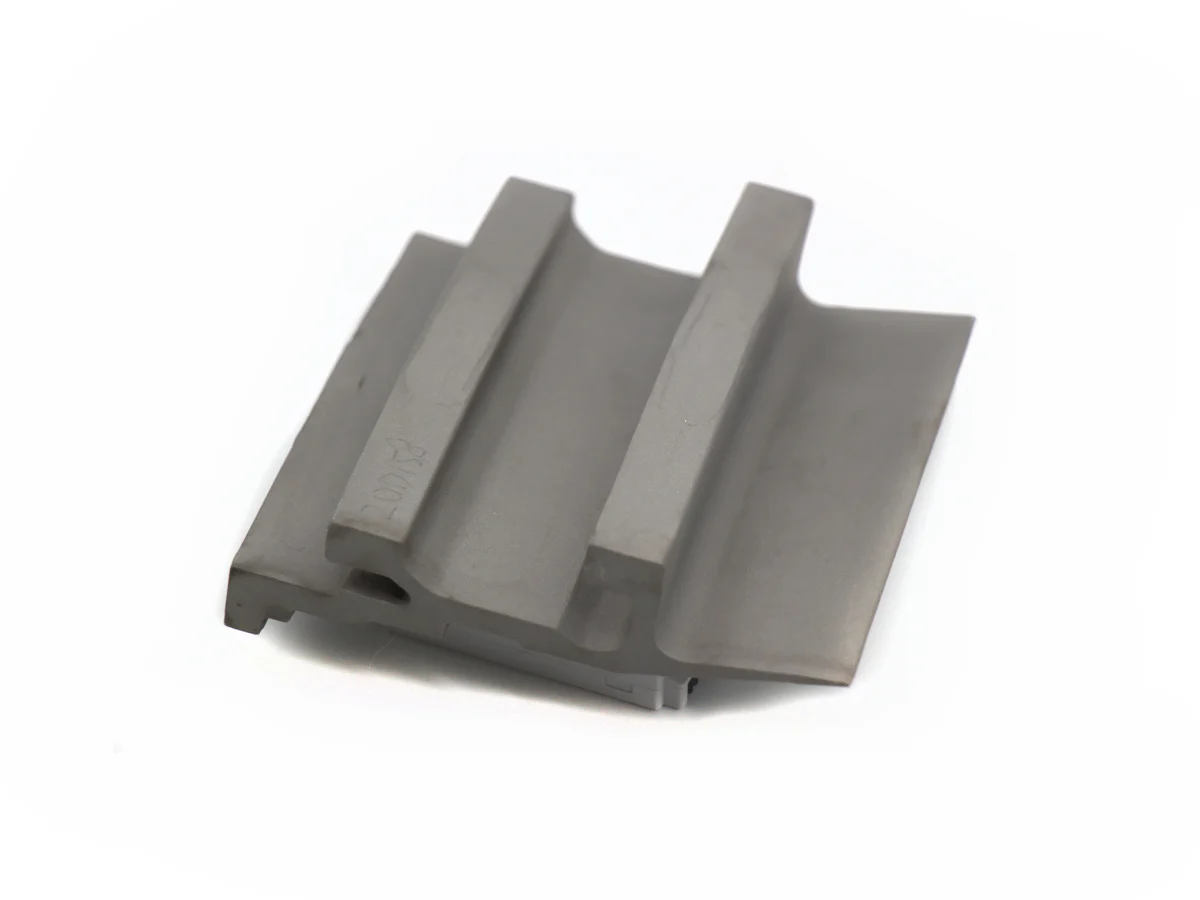

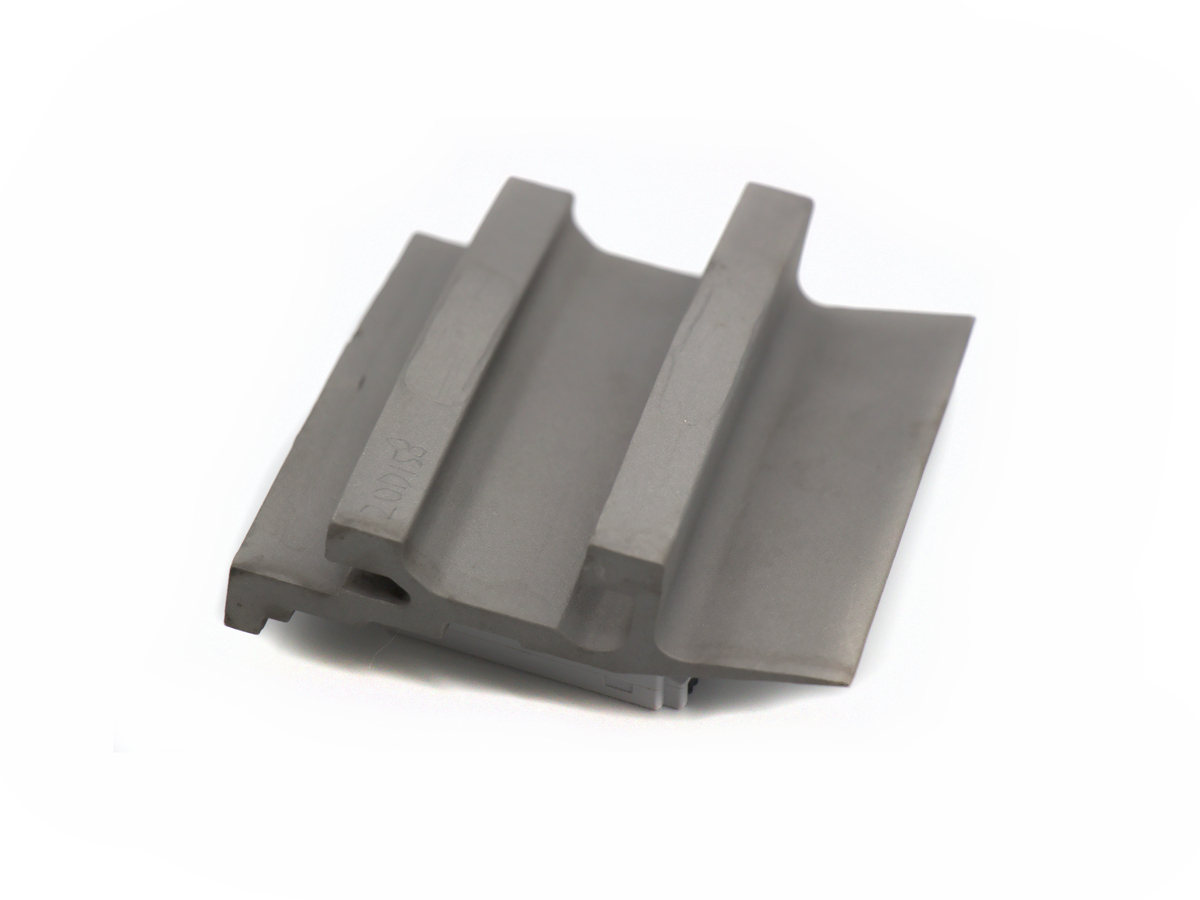

- High-temperature alloy assemblies

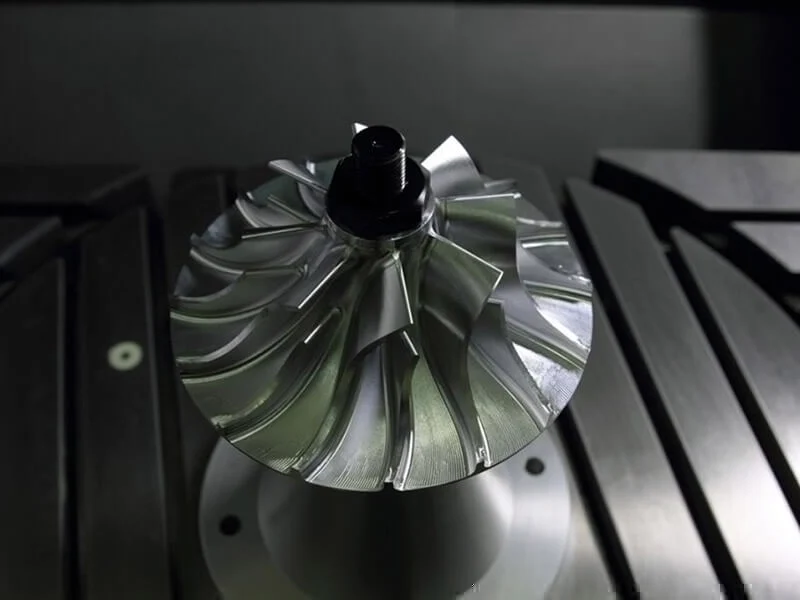

- Key gas turbine components

- Heat-resistant parts for power plants

Key Technologies

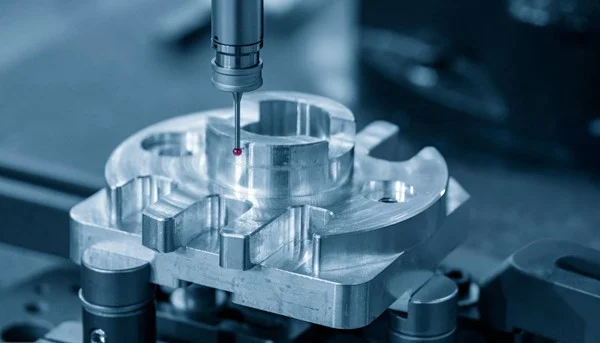

Highlighting sol-gel precision casting, advanced precision machining, and surface treatment technologies that deliver superior performance and durability.

Quality Control System

Comprehensive quality inspection processes adhering to international standards and export certifications ensure reliability and excellence.

Special Services

Customized design solutions and mass production capabilities with monthly output exceeding 1.3 million units.

Industry Applications & Case Studies

Core Industries Served

VastPCC proudly serves the aerospace gas turbines, nuclear power, and marine engineering sectors, delivering high-performance components engineered for durability and reliability.

- Gas turbine components designed for extreme high-temperature alloy durability

- Power plant parts optimized for long-term performance and reliability

- Marine engineering solutions tailored to rigorous operational demands

Application Insights

Detailed case studies highlight VastPCC’s expertise in manufacturing gas turbine and power plant components that meet stringent performance standards under extreme conditions.

Our components utilize advanced high-temperature alloys to ensure durability and operational excellence in demanding environments.

Global Clientele & Market Reach

VastPCC proudly serves over 40 export countries, partnering with key domestic and international customers to deliver industry-leading components worldwide.

Our commitment to quality and innovation has established VastPCC as a trusted supplier in aerospace, nuclear power, and marine engineering markets.

VastPCC Product Advantages & Quality Assurance

Material Strengths

Stainless steel, heat-resistant steel, and high-temperature alloys used for superior material performance, ensuring durability and reliability in the most demanding environments.

Process Benefits

Advanced manufacturing expertise in complex structures ensures precision and reliability, delivering products that meet exacting specifications every time.

Certifications & Standards

Compliance with international and domestic high-quality standards, backed by comprehensive third-party certifications to guarantee product excellence.

After-Sales & Technical Support

Robust warranty, troubleshooting assistance, and ongoing technical consultancy guarantees ensure your investment is protected and optimized.

Contact Us

Office Address: No 19 Jifa Road, Environmental Protection Industrial Park, Jimo, Qingdao, Shandong

Phone: +0086-13345064499 0086-0532-89069810

Email: postmaster@vast-cast.com

VastPCC FAQ & Industry Insights

What are common signs of gas turbine blade degradation?

Common signs include increased vibration, reduced power output, higher exhaust temperatures, and visual indications like cracks or erosion on the blades.

How often should gas turbine components be inspected?

Inspection frequency depends on operating conditions and OEM recommendations. Generally, hot gas path components should be inspected every 24,000 equivalent operating hours (EOH).

What materials are best for high-temperature gas turbine blades?

Nickel-based superalloys like Inconel and Mar-M are commonly used due to their excellent high-temperature strength, creep resistance, and oxidation resistance.

Embedded Keywords & Industry Focus

Our expertise covers gas turbine maintenance, high-temperature alloy performance, and power plant parts basics. VastPCC ensures you stay informed with the latest industry knowledge and best practices.

Leverage our insights to improve component longevity, optimize material selection, and understand advanced manufacturing techniques like precision casting.