Discover the precise density of brass alloys, factors affecting it, measurement methods, and comparisons to help with your material selection needs.

Density of Brass Explained Complete Guide with Alloy Types and Values

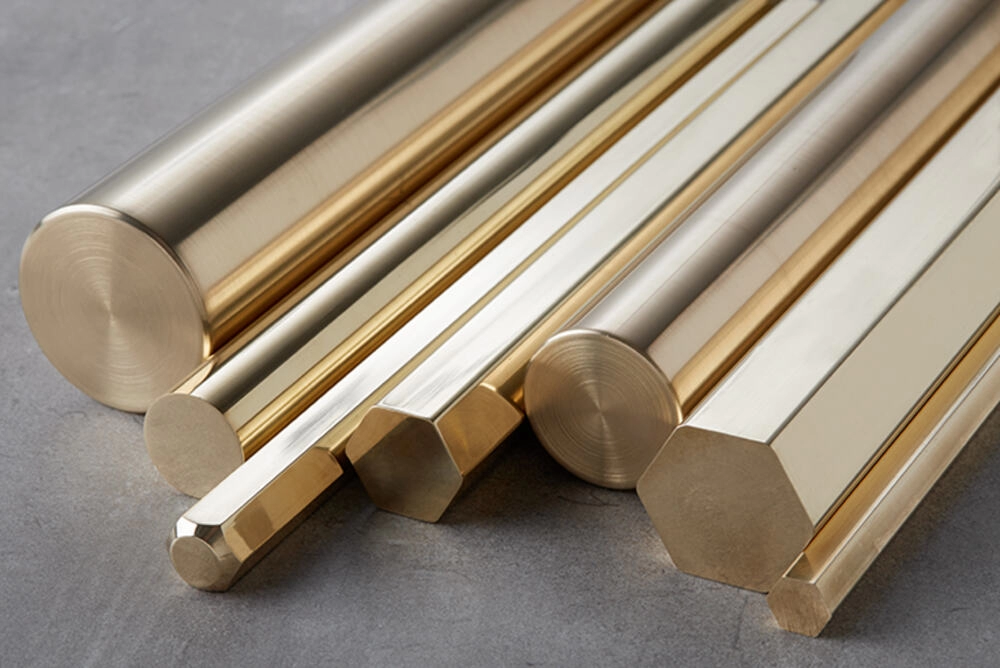

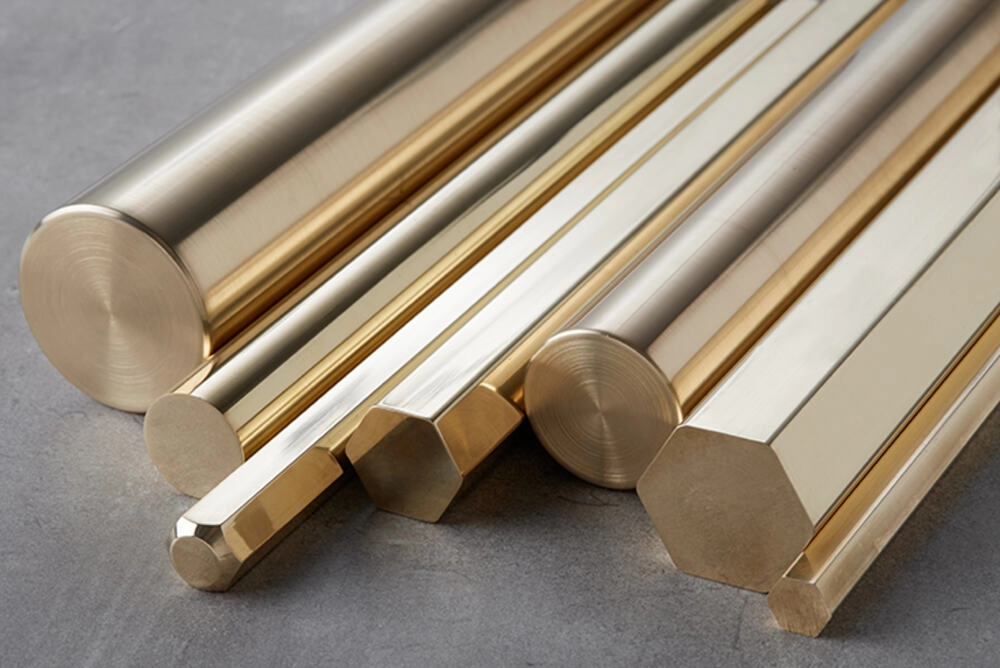

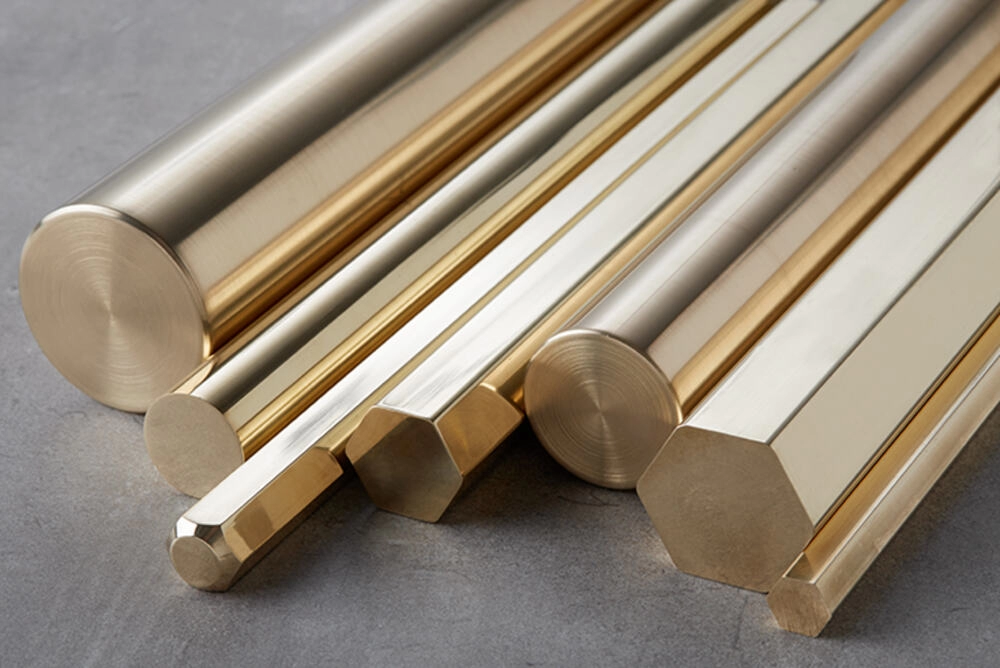

What Is Brass Composition and Types

Brass is a metal alloy primarily made of copper and zinc. The exact ratio of copper to zinc can vary, which creates different types of brass with unique properties. Typically, brass contains between 55% to 95% copper, with the remaining percentage being zinc. Small amounts of other elements like lead, tin, iron, or manganese may also be added to enhance specific characteristics.

Here are some common types of brass you’ll encounter:

- Cartridge Brass: Around 70% copper and 30% zinc, known for its strength and corrosion resistance.

- Yellow Brass: Typically 60% copper and 40% zinc; it’s bright and widely used in decorative applications.

- Red Brass: Contains about 85% copper and 15% zinc, often with a small amount of lead for better machinability.

- Naval Brass: Similar to cartridge brass but with a bit of tin added to improve corrosion resistance, especially in seawater.

- Free-Cutting Brass: Includes small amounts of lead (up to 3%) to make machining easier.

Each type of brass balances strength, workability, and appearance differently, which also impacts its density and other physical properties. Knowing the specific type of brass is essential when considering its density for your project or calculation.

What Is Density and Why Is It Important

Density is basically the weight of a material packed into a specific volume. In simple terms, it tells you how heavy something feels for its size. For brass, knowing its density helps us understand how much a piece will weigh and how it will perform in different applications.

Why does this matter? Well, if you’re working with brass for construction, manufacturing, or even investment casting, knowing the brass alloy density helps you predict strength, durability, and how the metal reacts under stress. It’s also crucial for calculating shipping costs and ensuring parts fit right where they need to go without surprises in weight or size.

In everyday terms, the density of brass (which is a mix of copper and zinc) affects everything from how heavy your hardware feels to how it handles heat and wear. So, whether you’re a manufacturer, engineer, or hobbyist, understanding density makes your work more precise and reliable.

The Density of Brass Standard Values

The density of brass varies depending on its exact composition but generally falls between 8.4 and 8.7 grams per cubic centimeter (g/cm³). In terms of pounds per cubic inch, that’s roughly 0.30 to 0.31 lbs/in³. This range is typical for most common brass alloys, which are primarily made up of copper and zinc.

Here are some standard brass density values based on common types:

- Cartridge Brass (70% copper, 30% zinc): 8.44 g/cm³

- Yellow Brass (60-70% copper, 30-40% zinc): 8.5 g/cm³

- Red Brass (85% copper, 5% zinc, 5% lead, 5% tin): 8.6 g/cm³

- Alpha Brass (more than 63% copper): around 8.5 – 8.7 g/cm³

Because brass is an alloy, these numbers can shift slightly if other metals like lead, tin, or iron are added. The specific gravity of brass—its density compared to water—is usually around 8.5, meaning brass is about 8.5 times heavier than water.

Knowing the density helps if you’re calculating the weight of brass components or using a brass weight calculator for projects, especially in investment casting or machining. It’s also vital for understanding how brass will perform in different applications where weight and strength matter.

Factors Affecting the Density of Brass

The density of brass isn’t fixed—it changes based on several factors. Primarily, the composition of the brass alloy plays a big role. Brass is mainly made of copper and zinc, but the exact ratio varies. More copper generally means higher density because copper is denser than zinc. Different types of brass, like alpha, beta, or leaded brass, have slightly different densities due to their unique compositions.

Other elements added for strength, machinability, or corrosion resistance—like lead, tin, or aluminum—also impact the density. These minor alloying elements can either increase or decrease the overall density depending on their own specific gravity.

Temperature affects density as well. When brass heats up, it expands, causing the density to decrease slightly. This is important during manufacturing or when brass parts operate in varying conditions.

Lastly, impurities or manufacturing methods can cause small variations in density. For example, investment casting brass may have slightly different density compared to wrought brass due to differences in structure or porosity.

Understanding these factors helps in predicting the weight of brass components and selecting the right type for your project based on the brass alloy density and physical properties.

How to Measure the Density of Brass

Measuring the density of brass is pretty straightforward and can be done with basic tools. Density is the weight of the brass per unit volume, usually expressed in grams per cubic centimeter (g/cm³) or pounds per cubic inch. Here’s how you can measure it:

- Weigh the Brass SampleUse a precise scale to find the weight of your brass piece. Make sure to measure in grams or pounds for easy calculations.

- Measure the VolumeFor regular shapes like rods or blocks, measure the dimensions (length, width, height, or diameter) and calculate the volume using standard geometric formulas.

For irregular shapes, use the water displacement method: submerge the brass piece in a graduated container filled with water and measure how much the water level rises. That rise equals the volume of your brass.Calculate DensityDivide the weight by the volume.

Density = Weight ÷ Volume

Using these steps, you can accurately find the density of your brass sample and compare it with standard values or use it to calculate specific gravity for quality checks. This method is similar to how most people measure the density of metals, making it practical whether you’re dealing with investment casting brass or other brass alloys.

Practical Applications Where Density of Brass Matters

Knowing the density of brass is key in many real-world uses. Since brass is a copper zinc alloy with variable density depending on its exact mix, understanding this helps in selecting the right type for the job.

- Manufacturing and Casting: For investment casting brass, precise density values ensure proper mold filling and avoiding defects. This helps in creating strong, accurate parts.

- Weight Calculation: When designing components like plumbing fixtures or musical instruments, knowing the weight of brass per cubic inch lets manufacturers predict overall weight. This is crucial for handling, shipping, and installation.

- Machining and Tooling: The density affects how brass behaves under machining processes. Knowing it guides tool choices and machining speeds to avoid waste or damage.

- Structural Applications: In construction or architectural hardware, brass density impacts strength and durability. Engineers use density info to balance between sturdiness and material cost.

- Jewelry and Decorative Items: The specific gravity of brass contributes to the feel and heft. Customers expect a certain weight to value the product, especially in the US market where quality signals matter.

- Recycling and Material Sorting: Accurate density data helps recycle centers classify metals quickly, improving efficiency and material recovery.

In all these cases, having a clear understanding of brass metal density and its variations by type makes a noticeable difference in product quality, cost-efficiency, and customer satisfaction.

Comparing Brass Density with Other Metals

Brass density usually falls between 8.4 and 8.7 grams per cubic centimeter (g/cm³), depending on its exact composition. This places brass right in the middle compared to other common metals you might be familiar with in the U.S. market.

Here’s a quick comparison:

- Aluminum: About 2.7 g/cm³ – much lighter than brass, great when weight savings matter.

- Copper: Around 8.96 g/cm³ – denser than brass since brass is mostly copper mixed with zinc.

- Steel: Typically 7.8 g/cm³ – slightly less dense, but usually stronger in terms of mechanical properties.

- Lead: Roughly 11.34 g/cm³ – significantly heavier than brass, often too dense for many applications.

If you need a metal that balances weight and strength, brass offers a good middle ground. You get more heft than aluminum but less than copper or lead, making it ideal for many uses like plumbing fixtures, musical instruments, and investment casting parts where density impacts performance and cost.

FAQs About Brass Density

What is the typical density of brass?

Brass density usually ranges between 8.4 and 8.7 grams per cubic centimeter, depending on its exact copper and zinc content.

How does the type of brass affect its density?

Different types of brass alloys have varying copper-to-zinc ratios, meaning their densities can change slightly. For example, a high-copper brass will be denser than one with more zinc.

Can I use the specific gravity to find brass density?

Yes, specific gravity is a way to compare brass density to water. Brass typically has a specific gravity around 8.5, which matches well with the density values in grams per cubic centimeter.

How do I accurately measure the density of brass at home or in the shop?

You can measure density by calculating the mass of the brass piece and dividing it by its volume. Volume can be found using water displacement if the shape is irregular. A precise scale and a container for water are needed.

Does temperature affect brass density?

Yes, like most metals, brass expands slightly when heated, which can lower its density. However, this change is usually small unless the temperature varies significantly.

Why is knowing the density of brass important for investment casting or manufacturing?

Density helps estimate the weight of brass parts, which matters for shipping costs, strength calculations, and meeting design specs—especially in the U.S. market where precise weights affect pricing.

Is brass heavier than steel or aluminum?

Brass is denser than aluminum but less dense than most types of steel. This makes it a good choice when you need a metal heavier than aluminum but lighter than steel.

Where can I find a brass weight calculator?

Online brass weight calculators can help you quickly determine weight by entering dimensions or volume, ideal for local metal suppliers and manufacturers across the U.S.

If you have more questions about brass alloy density, feel free to reach out or check local metalworking resources!