Discover titanium alloy properties, types, and applications with Vast expert insights on strength, corrosion resistance, and industry uses.

If you’re curious about titanium alloy and why it’s become a game-changer across industries, you’re in the right place. These unique metals combine strength, lightness, and corrosion resistance like few others can. Whether you’re an engineer, manufacturer, or just someone eager to understand what makes titanium alloys so valuable, this guide breaks down everything—from their key properties to real-world applications. Ready to discover why titanium alloy is shaping the future of materials? Let’s get started.

What Is Titanium Alloy

Titanium alloy is a metal made by combining pure titanium with other elements such as aluminum, vanadium, molybdenum, and iron. These added elements enhance titanium’s natural properties, making the alloy stronger, more durable, and better suited for specific uses compared to pure titanium.

Pure titanium itself is lightweight, corrosion-resistant, and biocompatible but lacks the strength and hardness needed for many industrial applications. By mixing in alloying elements, titanium alloys gain improved mechanical strength and resistance to heat, fatigue, and wear.

Titanium alloys are mainly classified into three types based on their microstructure:

- Alpha alloys: These contain mostly alpha phase titanium with small amounts of alloying elements. They offer good corrosion resistance, weldability, and strength but limited heat treatment options.

- Beta alloys: Primarily beta phase with alloying elements that stabilize this structure. They are highly formable and heat-treatable, with greater strength and toughness than alpha alloys.

- Alpha-beta alloys: These combine both alpha and beta phases, providing a balance of strength, ductility, and weldability. The most common example is Grade 5 titanium alloy, widely used in aerospace and medical fields.

This classification helps engineers choose the right alloy type for specific mechanical and temperature requirements while maintaining titanium’s unique benefits.

Key Properties of Titanium Alloys

Titanium alloys stand out because of their high strength to weight ratio. They deliver excellent strength while staying much lighter than steel, making them perfect for industries where saving weight is crucial.

These alloys also have impressive corrosion resistance. They resist rust and damage from chemicals, saltwater, and extreme weather, which is why they’re common in marine and chemical equipment.

When it comes to heat resistance, titanium alloys handle high temperatures well without losing strength. This makes them suitable for aerospace and automotive parts that face extreme conditions.

Another big plus is biocompatibility. Titanium alloys don’t react negatively inside the human body, which is why they’re widely used in medical implants and devices.

Titanium alloys also show excellent fatigue resistance and durability, meaning they withstand repeated stress and last longer than many other metals.

Here’s a quick comparison with aluminum and steel:

| Property | Titanium Alloy | Aluminum | Steel |

|---|---|---|---|

| Strength to Weight | Very High | Moderate | High (but heavier) |

| Corrosion Resistance | Excellent | Moderate to Poor | Variable (prone to rust) |

| Heat Resistance | High | Low to Moderate | Moderate to High |

| Biocompatibility | Excellent | Poor | Poor |

| Fatigue Resistance | Excellent | Moderate | Good |

Overall, titanium alloys offer a rare mix of strength, lightness, and durability that aluminum and steel can’t match easily.

Types and Grades of Titanium Alloys

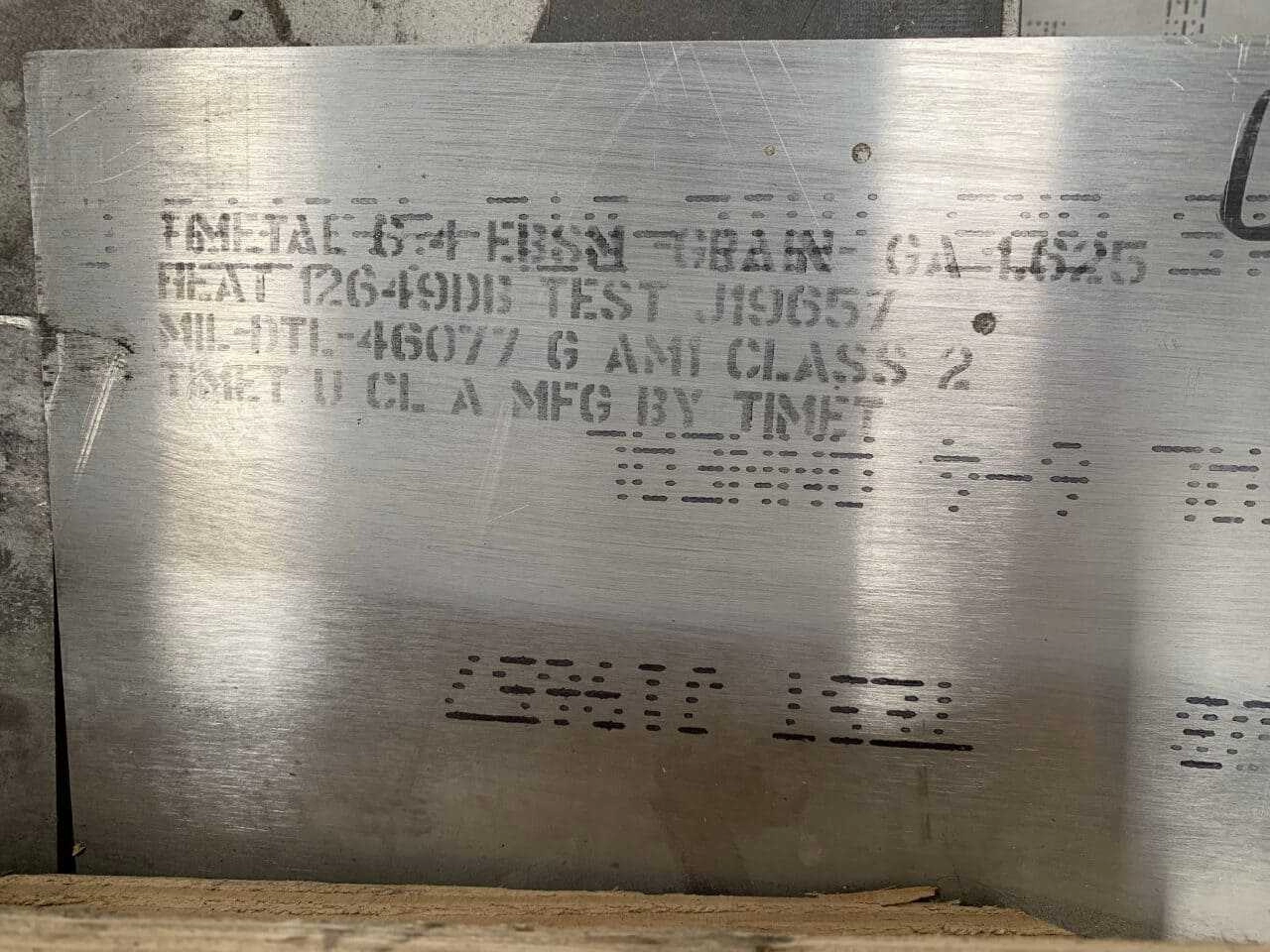

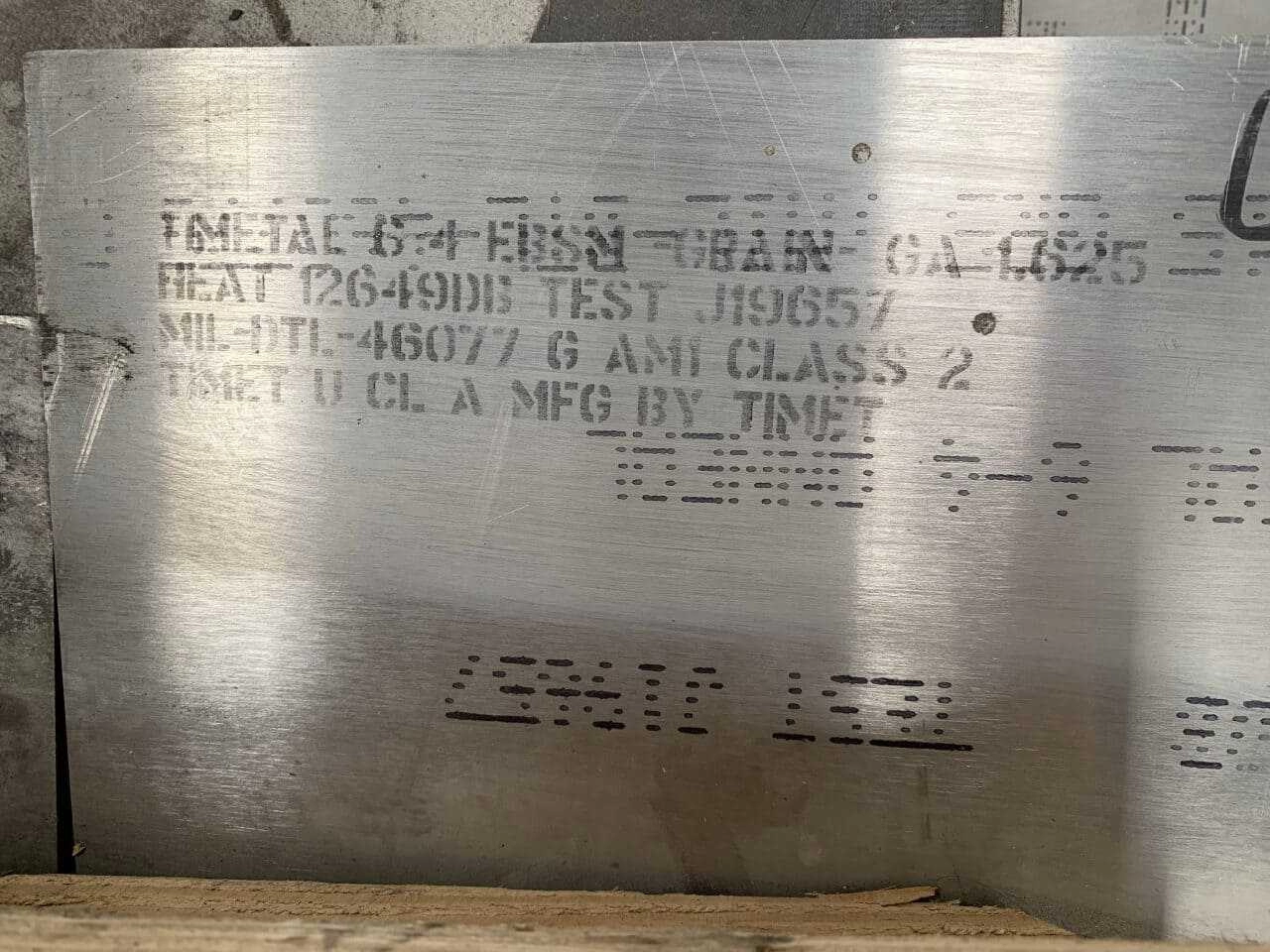

Titanium alloys come in several grades, each with unique properties suited for different uses. The most popular are Grade 2 and Grade 5.

- Grade 2 is commercially pure titanium. It’s known for excellent corrosion resistance and good ductility. This makes it a top choice for marine environments, chemical processing, and medical implants where biocompatibility matters.

- Grade 5, also called Ti-6Al-4V, is the most widely used titanium alloy. It contains aluminum and vanadium, which boost strength and heat resistance. Grade 5 is common in aerospace, automotive, and high-performance sports equipment.

Other notable grades include Grade 9 (Ti-3Al-2.5V), which offers a balance of strength and weldability, and Grade 23 (a variation of Grade 5 with extra purity) often used in medical and dental implants.

How Alloying Elements Affect Properties

- Aluminum increases strength and heat resistance, making alloys like Grade 5 tougher.

- Vanadium enhances toughness and fatigue resistance.

- Molybdenum improves corrosion resistance and adds strength, especially in beta titanium alloys.

Choosing the right grade often depends on the balance between strength, corrosion resistance, and cost for your project.

Manufacturing and Processing of Titanium Alloys

Titanium alloys are processed using several common methods depending on the final product. Forging is widely used to shape the metal under high pressure, improving strength and grain structure. Casting allows for creating complex shapes but requires careful control due to titanium’s reactivity at high temperatures. Machining titanium alloys needs specialized tools since they’re tougher than many metals, and improper machining can cause tool wear or overheating.

Working with titanium alloys has its challenges. The metal reacts easily with air and moisture when hot, so processing often requires an inert atmosphere or vacuum to prevent contamination. Also, titanium’s poor thermal conductivity means heat builds up quickly during machining, increasing the risk of cracks or surface damage.

Applications of Titanium Alloys

Titanium alloys are popular across many industries in the U.S. because of their strength, light weight, and corrosion resistance. Here’s where you’ll commonly find them:

- Aerospace and Aviation: Titanium alloys are crucial in aircraft parts like engines, airframes, and landing gears. Their high strength-to-weight ratio helps improve fuel efficiency and performance.

- Medical Implants and Devices: Thanks to excellent biocompatibility, titanium alloys are used for joint replacements, dental implants, and surgical instruments, reducing risks of rejection and corrosion inside the body.

- Automotive Industry: More manufacturers use titanium alloys in high-performance cars for components such as exhaust systems, connecting rods, and suspension parts where durability and weight savings matter.

- Marine and Chemical Processing Equipment: Their resistance to saltwater corrosion makes titanium alloys ideal for underwater components, ship parts, and equipment exposed to harsh chemicals.

- Sports Equipment and Consumer Goods: From golf clubs and tennis rackets to watches and eyeglass frames, titanium alloys provide durability without adding bulk, boosting comfort and performance.

- Emerging Applications: The renewable energy sector is starting to adopt titanium alloys in wind turbines and solar plants where material longevity and corrosion resistance reduce maintenance needs.

These diverse uses highlight why titanium alloys remain a go-to choice for projects demanding strength, lightness, and durability.

Benefits of Using Titanium Alloys in Industry

Titanium alloys bring several advantages that make them a top choice across industries. Here’s why they stand out:

Lightweight and Strength Advantages

- High strength-to-weight ratio means parts are strong but much lighter than steel.

- This reduces overall product weight, improving fuel efficiency in aerospace and automotive sectors.

Longevity and Reduced Maintenance Costs

- Corrosion resistance keeps titanium parts from rusting or degrading over time.

- Durable nature means fewer replacements and less downtime, saving money long term.

Enhanced Performance and Safety

- Excellent fatigue resistance and toughness ensure reliability in demanding applications.

- Critical industries like medical implants and aerospace rely on titanium for safety and consistent performance.

Environmental Benefits

- Titanium is highly recyclable, supporting sustainability goals.

- Its resistance to wear and corrosion reduces the need for frequent replacements, lowering material waste and energy use in manufacturing.

| Benefit | Impact |

|---|---|

| Lightweight strength | Improves efficiency and reduces energy use |

| Longevity | Lowers maintenance and replacement costs |

| Enhanced safety | Increases reliability in critical uses |

| Environmental impact | Supports sustainability and recyclability |

Choosing titanium alloys delivers real value by combining performance and eco-friendly benefits suited to today’s industrial needs.

How to Choose the Right Titanium Alloy for Your Project

Selecting the right titanium alloy depends on a few key factors:

Mechanical Requirements

- Strength and weight: Do you need high strength or lightweight materials?

- Fatigue and durability: Will the part face repeated stress?

- Heat tolerance: Does your project involve high temperatures?

Environmental Conditions

- Corrosion resistance: Is the alloy exposed to saltwater, chemicals, or humidity?

- Biocompatibility: For medical uses, compatibility with the body is crucial.

Budget and Cost

- Material costs vary significantly between grades.

- Manufacturing complexity can affect your overall expenses.

| Factor | What to Consider | Example |

|---|---|---|

| Strength | Load, stress type | Aerospace parts require high strength |

| Corrosion | Exposure to harsh environments | Marine equipment needs saltwater resistance |

| Machinability | Ease of fabrication | Some alloys machine better, cutting costs |

| Cost | Budget constraints | Grade 2 is cheaper but less strong than Grade 5 |

Common Challenges and Solutions When Working with Titanium Alloys

Working with titanium alloys brings some unique challenges, especially for U.S. businesses looking to get the most out of this material.

Cost considerations

Titanium alloys tend to be more expensive than aluminum or steel due to raw material prices and processing demands. To manage costs:

- Buy in bulk from trusted suppliers like Vast to get better pricing

- Select the right grade that fits your project needs without over-specifying

- Optimize design to reduce waste and machining time

Machining difficulties and solutions

Titanium is tough to machine because it’s strong and has low thermal conductivity, which can lead to tool wear and heat build-up. To tackle this:

- Use sharp, coated cutting tools specifically designed for titanium

- Employ lower cutting speeds and higher feed rates to reduce heat

- Apply proper coolant to keep the material and tools cool during machining

Prevention of corrosion in specific environments

While titanium alloys naturally resist corrosion, some environments like strong acids or saltwater can still cause issues. To prevent corrosion:

- Choose the right alloy grade for the environment (Grade 5 is great for marine, for example)

- Use protective coatings or surface treatments if exposure is severe

- Regularly inspect and maintain parts to catch early signs of corrosion

Addressing these common concerns helps you take full advantage of titanium alloy properties while avoiding costly delays or failures.

Future Trends and Innovations in Titanium Alloys

Titanium alloys are evolving fast thanks to continuous research and better technology. New alloy developments focus on improving strength, corrosion resistance, and heat tolerance while reducing weight even further. Researchers are also working on alloys that offer better machinability, which helps cut down manufacturing costs.

On the processing side, advances like additive manufacturing (3D printing) are opening doors to more complex designs and faster production times. This tech allows for lighter, stronger parts with less waste compared to traditional methods like forging or casting.

We’re also seeing titanium alloys move into new fields, such as renewable energy components and next-gen electric vehicles. Other emerging areas include advanced medical devices and even consumer electronics, where the combo of durability and lightness is key.

In short, titanium alloy innovation is gearing toward making materials that perform better, cost less to produce, and can be used in a wider range of industries than ever before.

Why Choose Vast for Your Titanium Alloy Needs

When it comes to titanium alloy solutions, Vast stands out for its deep expertise in the industry. We understand the unique properties and challenges involved in working with titanium alloys, helping you get exactly what your project demands.

What Vast Offers

- Industry Experience: Years of working with various titanium alloy grades like Grade 5 and Grade 2.

- Quality Assurance: Rigorous testing and quality control to ensure every batch meets high standards.

- Customization Options: Tailored alloy compositions and processing to fit your specific requirements.

- Reliable Supply: Consistent inventory and prompt delivery to keep your projects on track.

Customer Success Stories

Clients across aerospace, medical, and automotive sectors have trusted Vast for tough applications requiring corrosion resistance, strength, and lightweight performance. Many report improved durability and project efficiency thanks to our expertise.

Contacting Vastpcc

Ready to discuss your titanium alloy needs?

| Contact Method | Details |

|---|---|

| Phone | 0086-13345064499 |

| postmaster@vast-cast.com | |

| Website Contact Form | www.vastpcc.com |

Reach out anytime for quotes, technical advice, or custom orders. Vast is here to make sourcing titanium alloys straightforward and reliable.