Learn expert aluminum engraving techniques with fiber and CO2 lasers for high-contrast durable marks on raw and anodized metal surfaces.

Understanding Aluminum Types and Their Engraving Challenges

Aluminum comes in several forms, each with its own set of engraving challenges. Raw, bare aluminum is commonly used but offers low contrast when engraved because of its shiny, reflective surface. Its excellent heat dissipation and high thermal conductivity make it harder for laser energy to leave a visible mark. Plus, bare aluminum can oxidize quickly, causing whitish discoloration or “whitening” that reduces clarity. On the other hand, anodized aluminum features a durable oxide layer that provides a natural high contrast when engraved, making it a favorite for permanent, sharp marks. Coated or painted aluminum requires careful removal of the surface layer to reveal clean designs underneath.

A few common hurdles stand out across all types: low contrast on bare metal, challenges from oxidation, and aluminum’s high boiling point of 2470°C, which demands precise laser settings to avoid damage or poor marks. For CO2 laser users, applying a marking spray can significantly boost laser absorption on bare or coated aluminum, improving the quality and depth of engraving.

To visualize these differences, check out our infographic comparing engraving results on popular alloys like 6061 and 380. Curious to learn more and pick the right aluminum alloy for your project? Download VastPCC’s free aluminum alloy guide and start engraving with confidence.

Laser Engraving Aluminum The Gold Standard Technique

When it comes to aluminum engraving, laser engraving stands out as the top choice for precision and speed. But what type of laser works best? Fiber lasers and CO2 lasers both have their strengths, so let’s break it down.

Fiber Lasers vs CO2 Lasers for AluminumFiber Lasers

Best for bare aluminum and metals

Use a 1-micrometer wavelength for deep, fast etches

Great for detailed work and permanent markings

Example: VastPCC’s compact 20W fiber laser models deliver sharp, clear engravings quicklyCO2 Lasers

Better suited for anodized or coated aluminum sheets

Needs marking spray to boost contrast on bare metal

Ideal for surface treatments and lighter etching

Hybrid laser systems offer versatility for mixed materialsStep by Step Guide to Laser Engraving AluminumChoose your material – Pick the right aluminum type (bare, anodized, or coated) for your project.

Surface preparation – Clean the surface with acetone for dust and oils removal.

Software setup – Use LightBurn or similar software for your vector designs.

Optimal settings:

Power: 40 to 100W depending on thickness and detail

Speed: 200 to 500 mm/s for clean cuts

Passes: 1 to 3 for desired depthExecuting the engraving – Keep the material cool during the process to prevent warping.

Post-processing – Polish the surface for a smooth, shiny finish.Real World Example

A VastPCC client recently used fiber laser engraving to add QR codes on aluminum billets. This helped them track parts with precision and ensured top-notch traceability adding value to their manufacturing process.

How to Laser Engrave Aluminum

For a simple start, follow these steps (perfect for beginners):

- Clean aluminum with acetone

- Import your design into LightBurn

- Set laser power to 60W (adjust as needed)

- Set speed to 300 mm/s

- Run 1 to 2 passes

- Cool and polish the finished piece

This method works well on most aluminum surfaces and gets you great results every time.

Alt text example for process image:

“Laser fiber engraving machine marking a QR code on an aluminum billet with precise settings displayed on a laptop screen.”

If you want reliable, fast, and accurate aluminum engraving, fiber lasers from VastPCC are the go-to tool for professionals and hobbyists alike.

Alternative Methods CNC Rotary and Hand Engraving for Aluminum

If laser engraving isn’t an option, CNC rotary and hand engraving are solid alternatives for aluminum.

CNC Milling for Deep Engraving

Using carbide bits (like a 1/16” flat end) on machines such as VastPCC’s entry-level routers, CNC milling can carve deep, precise designs. It’s perfect for plaques or heavy-duty items where depth matters.

Pros: High depth and accuracy

Cons: Slower process compared to lasers

Rotary and Mechanical Engraving

Pantograph tools work well for fine details, especially on anodized aluminum sheets about 0.8mm thick. This method is budget-friendly and great for small runs or personalized orders.

Best for: Small batch jobs, simple designs, anodized sheets

Hand and Chemical Etching Basics

For DIY projects, a Dremel with diamond bits offers flexibility for custom artwork on aluminum. Chemical etching kits can create intricate patterns but require safety measures like good ventilation and gloves.

Remember: Always prioritize safety when handling chemicals and power tools

Comparison Table

| Method | Speed | Depth | Cost | Best For |

|---|---|---|---|---|

| Fiber Laser | Fast | Medium | $$ | Industrial, detailed marking |

| CNC Rotary Milling | Medium | High | $$$ | Deep engravings, plaques |

| Mechanical Engraving | Medium | Low-Medium | $ | Small runs, anodized sheets |

| Hand/Chemical Etching | Slow | Low | $ | Custom DIY, artistic projects |

Each method fits different needs depending on your aluminum engraving goals, budget, and volume.

Applications of Aluminum Engraving From DIY to Industrial Scale

Aluminum engraving works great for a wide range of projects, whether you’re a DIY enthusiast or running a full-scale industrial operation.

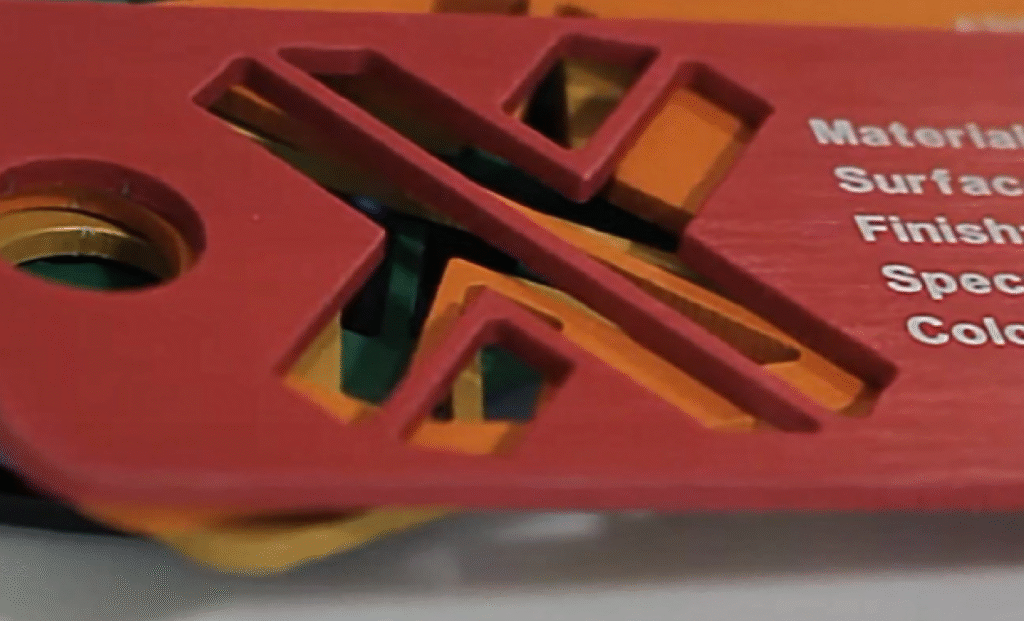

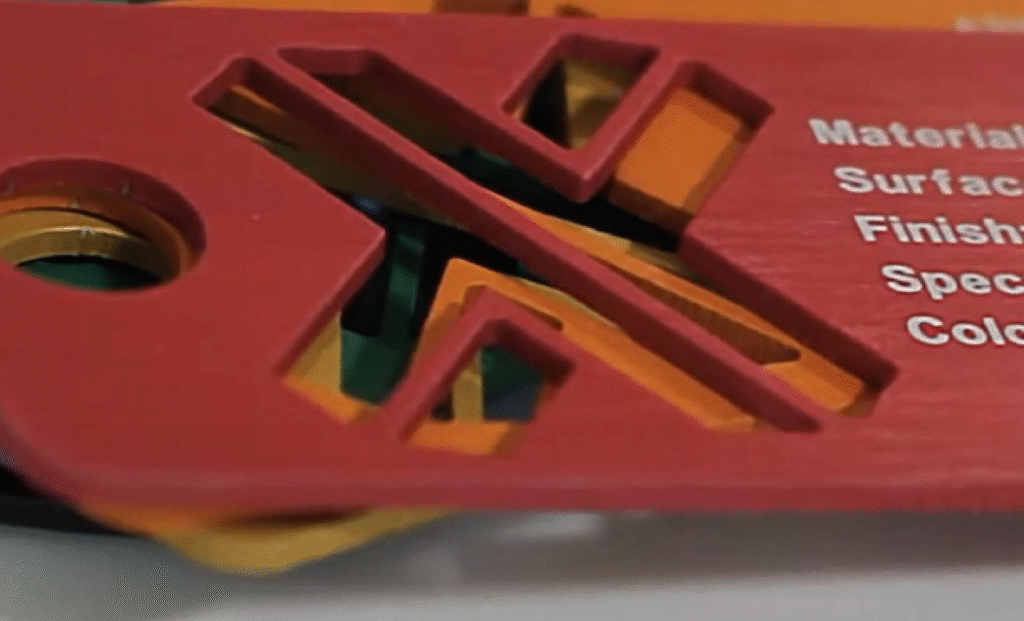

Personalization Projects

From custom awards and pet tags to nameplates, aluminum offers durable and attractive options. You can choose from a variety of finishes, including gold over silver blanks, to get just the right look that stands out and lasts. These projects are perfect for small businesses, hobbyists, or anyone wanting a personal touch on a gift or product.

Industrial and Commercial Uses

In the industrial world, aluminum engraving helps track and label parts with serial numbers on automotive components, data plates on electronics, and other compliance tags. These marks ensure traceability and meet strict regulations, making aluminum engraving a trusted choice for manufacturing and quality control.

Creative Inspirations

Engraving isn’t just functional—it’s fun too. Think engraved backsplashes, bottle openers, and other creative products. Many of our VastPCC customers share inspiring ideas that combine art and durability, showing how aluminum engraving unlocks new ways to customize everyday items.

Local Angle for US Customers

Tailoring engraving projects to local needs is key here in the US. Whether it’s custom signs for trade shows, corporate events, or region-specific branding, aluminum engraving offers flexibility to match your community’s style and standards. This local focus helps businesses make a lasting impression and meet market expectations with ease.

For anyone ready to dive into aluminum engraving, VastPCC provides resources and equipment tailored for every level—from DIY crafts to high-volume industrial marking. Check out our full aluminum alloy guide to get started today!

Tips Troubleshooting and Best Practices for Flawless Results

Getting clean, high-contrast aluminum engraving takes some care. Here are key pointers to make your marks sharp and long-lasting:

Achieving High Contrast and Durability

- Anodize after engraving if possible to boost contrast and protect the surface.

- Avoid overheating to prevent overburn, which causes blurry edges and discoloration.

- Use the right power and speed settings based on your aluminum type—too much power kills detail, too little results in faint marks.

Common Mistakes and How to Fix Them

- Fading marks: Try increasing passes but balance to avoid damage.

- Poor adhesion or patchy marks: Prep the surface well—clean with acetone or use primers made for laser marking.

- Diode laser limits: For bare aluminum, diode lasers struggle with contrast. Consider marking sprays or switching to fiber lasers for metals.

- Check online communities like Reddit for real-user insights on troubleshooting and tweaks.

Safety and Sustainability

- Always wear proper PPE like safety glasses and gloves when engraving.

- Use fume extraction systems to remove harmful particles.

- Consider eco-friendly lasers that lower power consumption and produce less waste.

10 Point Pre Engraving Checklist

- Clean surface thoroughly (acetone recommended)

- Choose correct aluminum type and verify alloy

- Set power and speed to manufacturer recommendations

- Test mark on scrap piece first

- Check focus for precise laser beam

- Use marking spray if bare aluminum

- Allow work area ventilation

- Plan for post-processing like polishing

- Inspect for oxidation or coating flaws

- Confirm file setup and software parameters

Following these steps will save time and ensure each aluminum engraving project comes out crisp, clear, and durable every time.

Choosing the Right Tools Recommendations from VastPCC

Picking the right tool for aluminum engraving is key to getting great results without breaking the bank. For those just starting out or working on smaller projects, entry-level options like diode, fiber, and hybrid lasers under $1,000 offer solid performance and versatility. These are perfect for DIYers and small businesses looking to engrave anodized sheets or bare aluminum with good contrast.

For pros and heavy users, VastPCC’s autofocus fiber laser markers stand out. Designed for 24/7 production, they deliver fast, precise engraving on all types of aluminum alloys, including 6061 and 380 series. These systems are built to handle high-volume industrial work with minimal downtime.

Where to buy? For local sourcing, check out authorized dealers or visit online marketplaces like Amazon for anodized aluminum blanks and engraving supplies. You’ll find a variety of materials ready for laser marking and engraving.

Ready to upgrade your setup? Schedule a free VastPCC demo today and get personalized recommendations for your custom aluminum engraving needs.