Discover the benefits and uses of zinc plated metal for durable corrosion resistance, cost-effective protection, and versatile industrial applications.

What is Zinc Plating The Science Behind the Shiny Shield The Electroplating Process Step-by-Step

Zinc plating is a popular surface treatment that gives metal parts a shiny, protective coating. It involves applying a thin layer of zinc onto a metal surface, usually steel, to shield it from rust and corrosion. This process is especially valuable for extending the life of metal components in environments where moisture and oxygen can cause damage.

The science behind zinc plating lies in its ability to act as a sacrificial anode. Zinc corrodes before the underlying metal, effectively protecting the base metal from rusting. This corrosion-resistant steel coating forms a durable barrier while maintaining the appearance and function of the metal piece.

The most common method of applying zinc plating is through the electroplating process, also known as electrogalvanizing. Here’s a simple step-by-step overview:

- Surface Preparation: The metal part is cleaned thoroughly to remove oils, dirt, and rust. This often includes degreasing and sometimes acid dipping to ensure the surface is perfectly clean.

- Rinsing: The part is rinsed with water to remove any residues from cleaning.

- Electroplating Bath: The metal is submerged in an electrolyte solution containing zinc ions.

- Applying Electric Current: An electrical current passes through the solution causing zinc ions to deposit evenly onto the metal surface.

- Rinsing and Drying: The plated part is rinsed again and dried to prevent water spots or corrosion during storage.

This controlled process results in a uniform zinc coating, typically measured in microns, which balances protection with cost effectiveness. Zinc plating not only boosts corrosion resistance but also improves the metal’s appearance with a bright, smooth finish. Understanding this science and the electroplating steps helps explain why zinc plated metal remains a trusted choice across industries and DIY enthusiasts alike.

What is Zinc Plating The Science Behind the Shiny Shield Types of Zinc Coatings Plating vs Alternatives

Zinc plating is more than just a shiny finish—it’s a smart way to protect metal from rust and corrosion. There are a few types of zinc coatings used depending on what the job calls for. The most common is electroplating (or electrogalvanizing), where a thin layer of zinc is applied through an electric current. This creates a smooth, even coat ideal for small parts and fasteners.

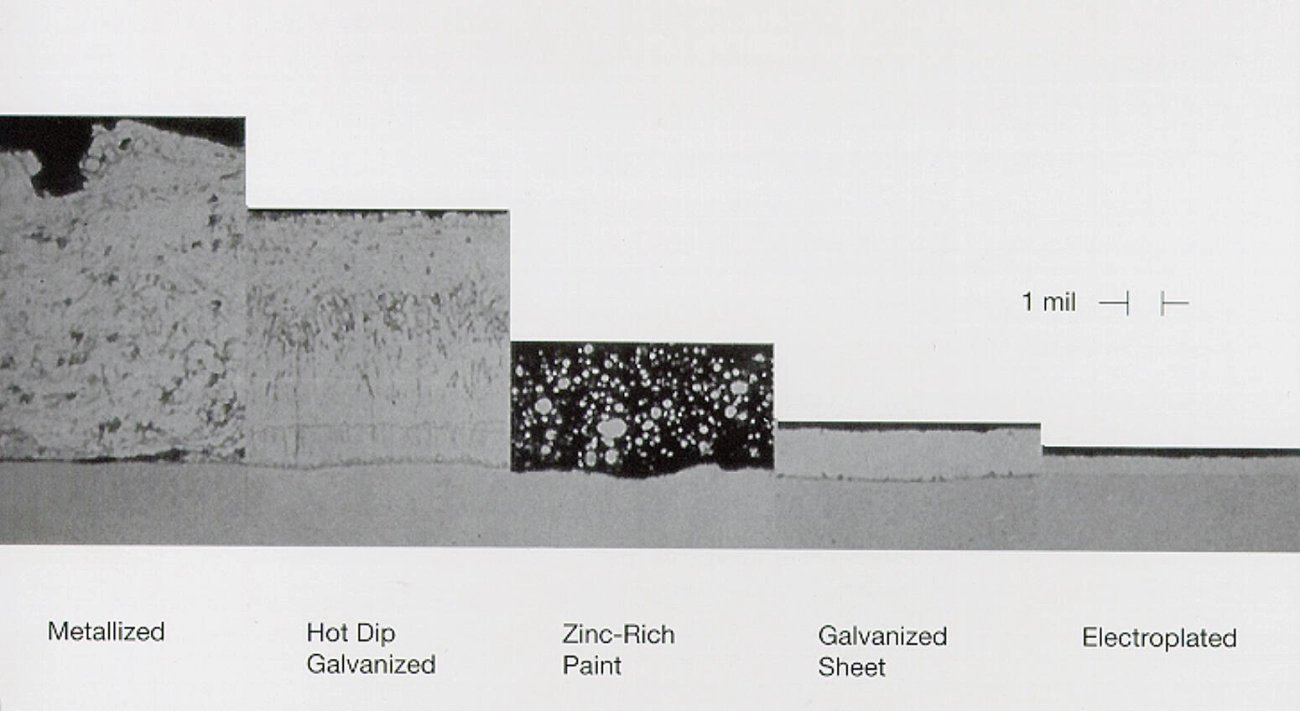

Other types include hot-dip galvanizing, where metal is dipped in molten zinc for a thicker, tougher layer, and zinc sprays or mechanical plating which are good for larger or oddly shaped pieces.

When comparing zinc plating to alternatives, here’s what stands out:

- Zinc Plating vs Hot-Dip GalvanizingZinc plating offers a thinner, more precise coating with a cleaner look, while hot-dip galvanizing delivers heavier corrosion resistance for outdoor or harsh environments.

- Zinc Plating vs Stainless SteelStainless steel resists corrosion naturally but costs more and can be heavier. Zinc plating provides sacrificial anode protection by corroding first, which saves the steel beneath.

- Zinc Plating vs Powder CoatingPowder coating adds color and thicker layers but may chip or crack over time. Zinc plating excels in corrosion resistance and allows easy finishing with paints or zinc chromate conversion coatings.

Understanding these types and alternatives can help you pick the best finish whether you’re working in automotive, construction, or just tackling a DIY project. The electrogalvanizing process follows ASTM B633 specifications, ensuring reliable corrosion-resistant steel coatings ideal for U.S. markets.

Key Benefits of Zinc Plated Metal Protection Affordability and Versatility Unmatched Corrosion Resistance and Longevity

When it comes to protecting metal, zinc plated metal stands out for its excellent corrosion resistance. The zinc layer acts as a sacrificial anode, meaning it corrodes first instead of the steel underneath. This gives your metal parts a longer life, especially in everyday environments like outdoors or humid areas.

Zinc plating also offers consistent protection thanks to controlled thickness measured in microns, ensuring your metal won’t rust easily. Compared to other coatings, zinc is tough enough to resist wear and tear, keeping the metal looking good and functioning well over time.

Because of this durability, zinc plated metal is incredibly versatile. Whether you’re working on automotive parts, construction fasteners, or DIY projects, it reliably guards against corrosion without adding much weight or bulk. This makes zinc plating a go-to for many industries across the U.S., especially where affordable yet durable metal protection is needed.

In short, zinc plated metal offers:

- Long-lasting corrosion resistance through sacrificial protection

- Durable coating thickness for consistent metal defense

- Versatility across a wide range of applications

- Cost-effective protection without compromising quality

That balance of affordability and performance is why zinc plating remains a top choice for corrosion-resistant steel coatings nationwide.

Key Benefits of Zinc Plated Metal Protection Affordability and Versatility Cost-Effective and Eco-Friendly Advantages

Zinc plated metal stands out not just for its protective qualities but also for being cost-effective and environmentally friendly. Compared to other metal coating methods, zinc plating typically uses less material and energy, which helps keep costs down and reduces the carbon footprint. This makes it a smart choice for businesses and DIY enthusiasts looking to protect metal parts without breaking the bank.

From an eco-friendly perspective, zinc is a naturally abundant metal and can be recycled easily. The electrogalvanizing process used in zinc plating produces fewer emissions compared to heavier coatings like hot-dip galvanizing. Plus, because zinc offers sacrificial anode protection, it extends the life of steel components, reducing the need for frequent replacements and preventing waste.

If you’re after a practical, budget-friendly surface treatment that also supports sustainability, zinc plated metal offers a solid balance between performance and environmental care.

Key Benefits of Zinc Plated Metal Protection Affordability and Versatility Aesthetic and Functional Enhancements

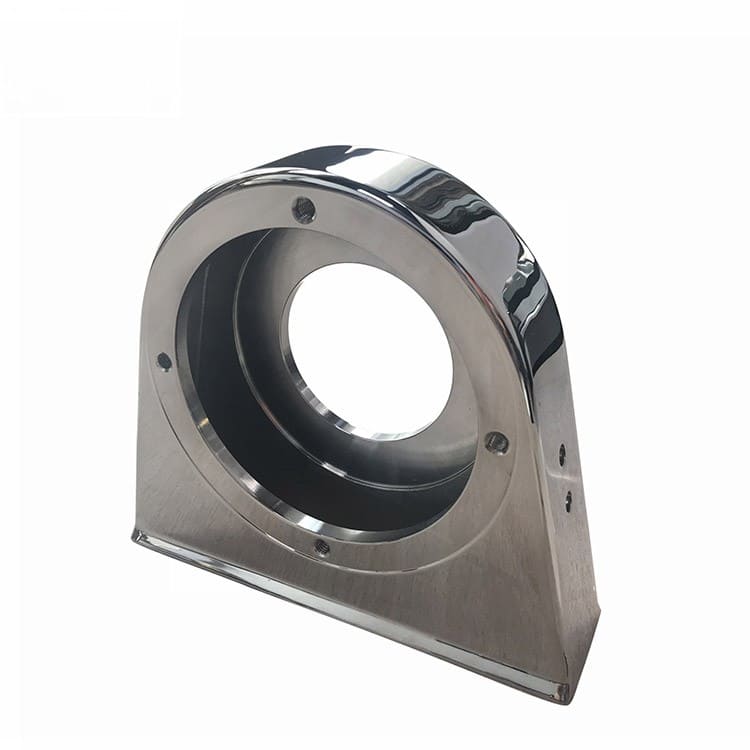

Zinc plated metal doesn’t just protect—it also looks good and works better. The shiny, smooth finish adds an attractive, clean look to parts and products, which is why it’s popular for visible hardware like fasteners and fixtures in homes and businesses across the U.S. This aesthetic boost means you get metal that’s not only tough but also fits well in modern spaces without needing extra painting or coating.

Functionally, the zinc layer improves durability by reducing wear and tear. It helps prevent rust spots from forming, which keeps metals strong longer and reduces the need for frequent replacements. This means less downtime for repairs and lower costs over time. Plus, zinc plating can improve electrical conductivity and reduce friction, which is a big plus in automotive and industrial parts.

Overall, zinc plated metal combines affordability with practical upgrades—making it a favorite for projects where looks, performance, and budget all matter.

Common Applications Where Zinc Plated Metal Excels Industrial and Automotive Uses

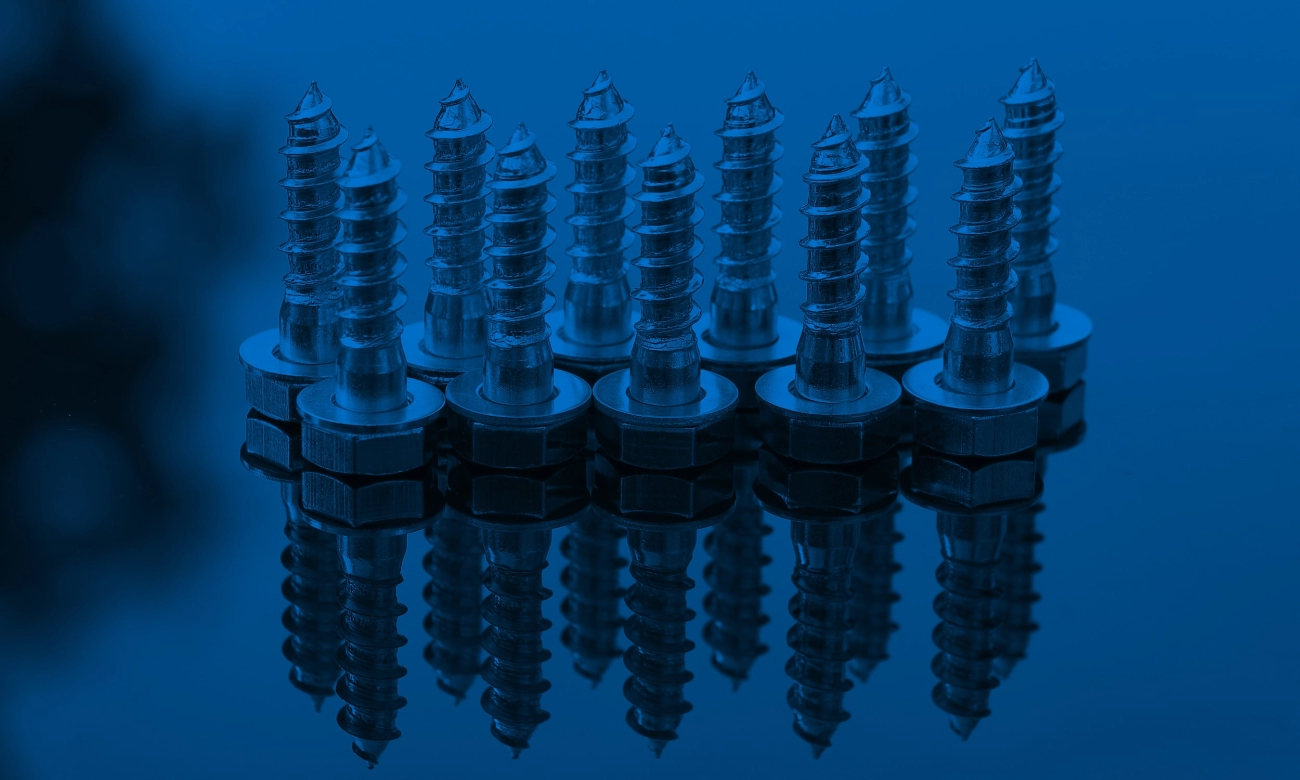

Zinc plated metal is a go-to choice in industrial and automotive settings because it offers solid protection against rust and wear. In factories and workshops, it’s commonly used for galvanized metal fasteners like screws, bolts, and nuts, which need to stand up to tough conditions without corroding. The electrogalvanizing process creates a consistent, thin zinc coating that keeps these parts durable and reliable.

In the automotive industry, zinc plating helps protect steel parts such as brake components, body panels, and chassis parts. The sacrificial anode protection zinc provides means even if the coating gets scratched, the metal underneath stays safe from corrosion. This is especially important for vehicles exposed to road salt, moisture, and changing weather seen in many parts of the U.S.

Because zinc plating meets ASTM B633 specifications, manufacturers trust it for dependable corrosion resistance. Plus, zinc’s ability to allow further surface treatments like zinc chromate conversion means parts can be finished for extra durability or to meet specific functional needs.

In short, zinc plated metal shines in harsh industrial and automotive environments by extending the life of critical components while keeping costs manageable.

Common Applications Where Zinc Plated Metal Excels Construction and DIY Projects

Zinc plated metal is a popular choice for construction and DIY projects across the United States because it offers reliable corrosion resistance without breaking the budget. Builders and hobbyists alike use zinc plated steel for fasteners like screws, nails, and bolts since the zinc coating protects these parts from rusting, especially in outdoor or humid environments.

In construction, zinc plating is often found on metal framing components, brackets, and hardware that need a durable finish but don’t require the heavy-duty protection of hot-dip galvanizing. Its thinner, smoother coating makes it perfect for parts that need to fit together precisely or where the appearance of a shiny, clean surface matters.

For DIY enthusiasts, zinc plated metal is ideal when working on projects like garden furniture, shelving, or small repairs. It provides an accessible way to extend the life of metal parts used in home improvements, saving money while improving longevity. Plus, the zinc plating process meets ASTM B633 specifications, ensuring consistent quality across coated parts.

Key benefits in construction and DIY include:

- Great corrosion resistance in moderate environments

- Smooth, bright finish for aesthetic appeal

- Easy to work with using standard tools

- Cost-effective compared to other coatings

- Meets safety standards for galvanized metal fasteners

Whether you’re framing a deck or fixing a gate, zinc plated metal gives you the balance of protection and affordability that fits well with most everyday construction and DIY tasks.

Common Applications Where Zinc Plated Metal Excels Limitations and When to Avoid It

Zinc plated metal is great for a lot of uses, especially when you want corrosion resistance without breaking the bank. It shines in indoor environments or places with light exposure to moisture, like car parts, household hardware, and electrical components. But it’s not a one-size-fits-all solution.

Here’s when you should think twice before choosing zinc plating:

- Heavy Outdoor Exposure: Prolonged exposure to rain, snow, or salty air (like coastal areas) can wear down zinc plating faster than hot-dip galvanizing. The thin zinc layer can chip or peel, leaving metal underneath vulnerable.

- High-Heat Environments: Zinc plating can lose its protective qualities when exposed to very high temperatures repeatedly. If your project involves heat, alternatives like stainless steel might do better.

- Mechanical Wear and Tear: Surfaces that get scratched, bumped, or abraded a lot may not hold zinc plating well over time. The protective layer is thin (often measured in microns), and damage can expose bare metal.

- Chemical Exposure: Strong acids, alkalis, or harsh cleaning chemicals quickly degrade zinc plated surfaces, reducing corrosion resistance.

In short, zinc plated metal works best where protection needs are moderate, and budget matters. For tougher conditions, consider alternatives like hot-dip galvanized steel or stainless steel. Knowing your application environment helps avoid problems and keeps your investment solid longer.

Zinc Plated Metal vs Competitors A Head-to-Head Comparison Zinc Plating vs Hot-Dip Galvanizing

When deciding between zinc plated metal and hot-dip galvanizing, it’s important to understand how each protects metal and where they shine.

Zinc plating uses the electrogalvanizing process to apply a thin zinc layer, typically measured in microns. This creates a smooth, shiny finish that’s great for indoor use or environments with mild corrosion exposure. It’s perfect when you need a clean look and moderate protection on fasteners, automotive parts, or light steel components. Zinc plating also meets ASTM B633 specifications, ensuring consistent quality.

Hot-dip galvanizing, on the other hand, involves dipping the metal into molten zinc. This results in a much thicker zinc coating, offering heavy-duty corrosion resistance. Hot-dip galvanized steel withstands harsh weather, making it ideal for outdoor structures like construction beams, guardrails, and heavy machinery. The thicker layer also means longer life, especially where sacrificial anode protection is critical.

Key differences include:

- Thickness: Hot-dip galvanizing coats metal with a thicker zinc layer, enhancing durability. Zinc plating’s thinner layer is more for light corrosion resistance.

- Appearance: Zinc plating gives a smoother, shinier surface, favoured when aesthetics matter. Hot-dip galvanizing can look rougher or matte due to the thick coating.

- Applications: Zinc plated metal works well indoors or for parts that won’t face extreme weather. Hot-dip galvanizing is best for outdoor and heavy-duty uses.

- Cost and turnaround: Zinc plating is usually quicker and less expensive, ideal for fast production runs of smaller parts. Hot-dip galvanizing requires longer processing but offers extended protection.

In , if your project demands solid protection in tough environments, hot-dip galvanizing is the go-to. For affordable, clean, and moderate corrosion protection, zinc plating provides an excellent balance. Understanding these differences helps you pick the right solution for your metal’s lifespan and appearance requirements.

Zinc Plated Metal vs Competitors A Head-to-Head Comparison Zinc Plating vs Stainless Steel and Powder Coating

When deciding between zinc plated metal, stainless steel, or powder coating, each has its strengths depending on the job.

Zinc Plating vs Stainless Steel

- Corrosion Resistance: Stainless steel naturally resists rust without extra coatings, making it ideal for harsh environments. Zinc plated metal relies on sacrificial anode protection, meaning the zinc layer corrodes first to protect the steel underneath. This works great for general corrosion resistance but isn’t as long-lasting as stainless steel in tough conditions.

- Cost: Zinc plated metal is much more affordable. Stainless steel costs up to several times more, so if you’re working on a budget but still want decent protection, zinc plating is the way to go.

- Strength and Durability: Stainless steel is stronger and more durable without worrying about the coating wearing off. Zinc plating does add a thin protective layer but can be scratched or damaged over time.

Zinc Plating vs Powder Coating

- Protection: Powder coating creates a thick, durable finish that offers excellent protection from corrosion and wear. Zinc plating provides a thinner corrosion-resistant layer but is prone to damage if mishandled.

- Appearance: Powder coating can be colored and has a smooth finish, perfect for aesthetic projects. Zinc plated metal has that classic shiny silver finish, which is functional but less customizable.

- Application: Zinc plating suits fasteners, automotive parts, and industrial uses where thin corrosion resistance suffices. Powder coating is common in consumer goods and outdoor furniture where extra color and durability are desired.

In short, zinc plated metal is a cost-effective option for corrosion resistance with a classic look, ideal for many everyday U.S. applications. Stainless steel is your choice for extreme durability and rust resistance, but at a higher price. Powder coating offers both protection and style but isn’t a metal coating—it’s a finish on top. Pick the right solution based on your budget, environment, and appearance needs.

Maintenance and Best Practices Maximizing Your Zinc Plated Investment Painting and Finishing Tips

To keep your zinc plated metal looking good and performing well, a little care goes a long way. Painting and finishing over zinc plating not only boosts its appearance but also adds extra protection against corrosion.

Here are some straightforward tips:

- Clean the surface first: Make sure the zinc plated metal is free from dirt, grease, or oils before painting. Use a mild detergent or a simple degreaser to prep the surface.

- Use zinc chromate conversion coating: This chemical treatment improves paint adhesion and adds another corrosion-resistant layer.

- Choose the right paint: Use paints designed for metal surfaces, such as acrylic or epoxy paints. These stick better and last longer on zinc plated metal.

- Apply primer when needed: Primers made for galvanized or zinc-coated metals help paint bond stronger, preventing peeling or flaking.

- Follow proper drying times: Let each coat dry fully before applying the next to avoid uneven finishes or bubbles.

- Avoid harsh chemicals: After painting, steer clear of cleaners with acids or abrasives that can eat into the zinc layer.

These steps can extend the life of your zinc plated metal, keep corrosion at bay, and maintain its neat, shiny appearance. Taking the time for proper painting and finishing makes your investment in zinc plating go further.

Maintenance and Best Practices Maximizing Your Zinc Plated Investment Safety and Long-Term Care

Taking good care of your zinc plated metal is key to keeping its corrosion-resistant steel coatings working strong over time. Here’s how to get the most out of your zinc plating investment:

- Regular Cleaning: Dirt, salt, and pollutants can speed up corrosion if left unchecked. Use mild soap and water to clean surfaces regularly. Avoid harsh chemicals that can damage the zinc chromate conversion layer.

- Avoid Scratches: Zinc plating offers sacrificial anode protection, but deep scratches expose raw metal and reduce this benefit. Handle with care during installation and use to keep the plating intact.

- Check Thickness Microns: Over time, zinc plating can wear down, especially in outdoor or high-friction environments. If possible, periodically measure zinc plating thickness microns to assess wear and consider re-plating if needed.

- Proper Storage: Store zinc plated metals in dry, cool areas to reduce risks of metal fume fever and other corrosion-related issues. Avoid damp or humid spaces that encourage rust development.

- Paint and Finish: For added protection, especially outdoors, consider finishing zinc plated metal with paint or sealants that meet ASTM B633 specifications. This helps extend longevity and keeps the metal looking its best.

- Safety First: When handling or working on zinc plated parts (like galvanized metal fasteners), wear protective gear. Proper ventilation reduces risks from fumes and particles, especially during welding or grinding.

By following these simple care steps, your zinc plated metal will maintain its strength, appearance, and durability for years to come.

Why Choose VastPCC for Your Zinc Plating Needs

When it comes to zinc plated metal, VastPCC stands out as a trusted partner for businesses and individuals across the U.S. Here’s why choosing us makes a difference:

- Expertise You Can Count OnWe specialize in the electrogalvanizing process and strictly follow ASTM B633 specifications to ensure every zinc coating is consistent and reliable.

- Tailored Solutions for Your ProjectWhether you need corrosion-resistant steel coatings for industrial parts or galvanized metal fasteners for construction, we customize thickness and finishes to match your exact needs.

- Advanced Technology and Quality ControlOur state-of-the-art plating lines maintain even zinc plating thickness microns, providing sacrificial anode protection that lasts longer in tough environments.

- Eco-Friendly and Safe PracticesWe prioritize environmentally responsible plating methods and keep safety top of mind to prevent metal fume fever, protecting our team and your product quality.

- Local Service with Nationwide ReachBased in the U.S., we understand local market demands and provide fast turnaround times, making VastPCC a reliable source for zinc plating on a wide range of metal surfaces.

- Support and Maintenance AdviceBeyond plating, we offer guidance on DIY metal surface preparation, painting tips, and long-term care to help you maximize the life of your zinc plated metal parts.

Choosing VastPCC means getting quality, durability, and service tailored to your zinc plating needs. Reach out today to see how we can protect and enhance your metal products.