Explore precision china sheet metal fabrication with Vastpcc offering custom laser cutting bending welding and fast prototypes for global industries

What Is Sheet Metal Fabrication and Why Choose China

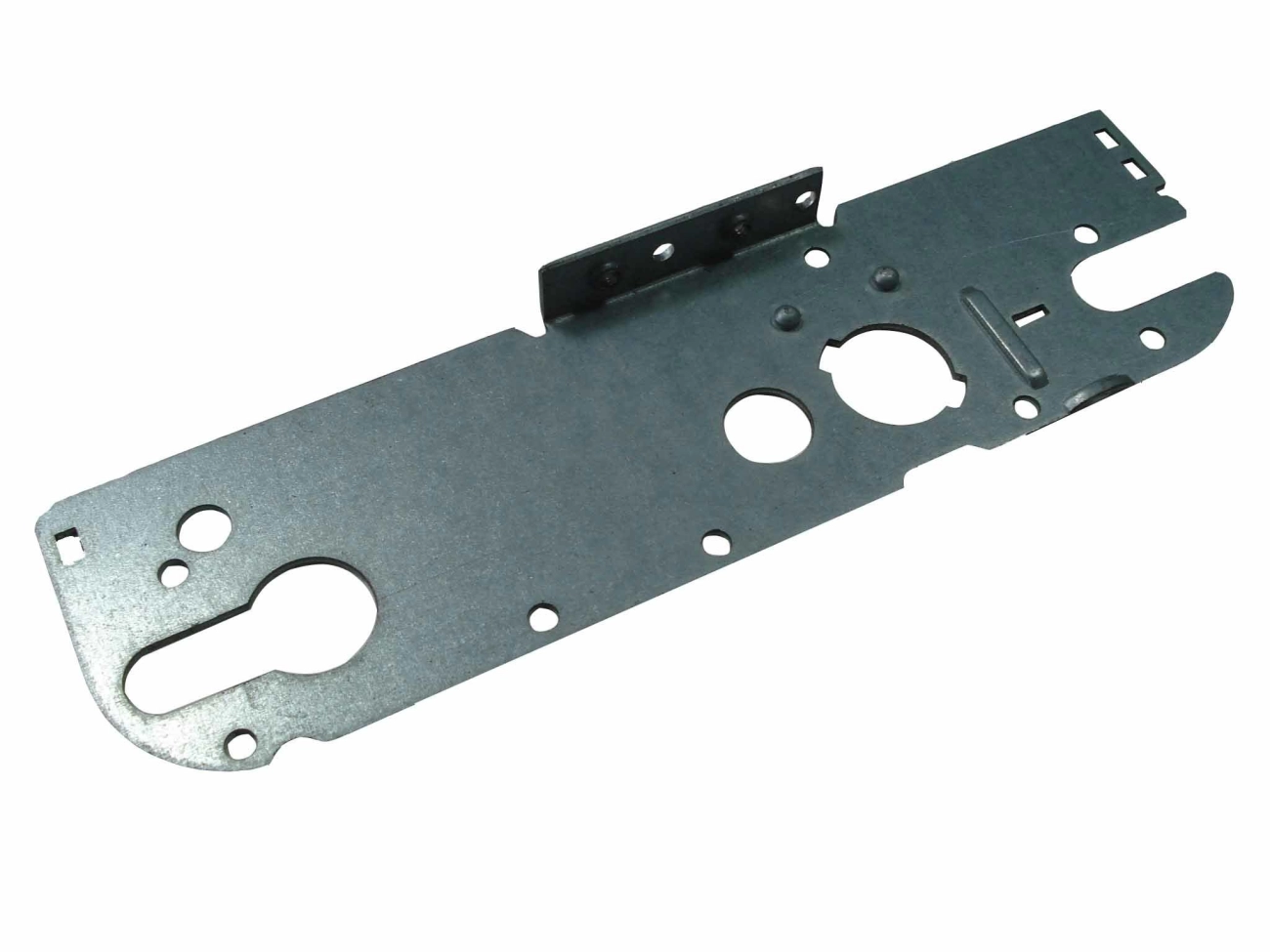

Sheet metal fabrication involves shaping and assembling thin metal sheets into custom parts used across many industries. It includes cutting, bending, stamping, welding, and finishing to create precise metal components tailored to specific needs.

Core Processes in Sheet Metal Fabrication

- Laser cutting: Uses focused laser beams for high precision and clean edges.

- CNC bending: Computer-controlled machines bend metal to exact angles.

- Stamping: Presses patterns or shapes into sheet metal quickly and consistently.

- Welding: Joins metal parts securely for strong assemblies.

- Assembly and finishing: Combines parts and applies treatments like powder coating or polishing.

The China Advantage Cost Speed and Scale

China remains a top choice for sheet metal fabrication thanks to its:

- Lower production costs that help businesses save on manufacturing.

- Fast lead times supported by efficient workflows and large workforce.

- Massive manufacturing scale enabling small or large batch orders.

- Wide range of factories specializing in custom sheet metal prototyping and large volume production alike.

Pros Cons and Mitigations

Working with Chinese sheet metal manufacturers comes with benefits and challenges:

- Pros: Cost-effective precision metal bending services, access to ISO-certified metal fabricators, strong capacity for low-volume sheet metal production.

- Cons: Potential quality variations, tariffs on imports to the US, and logistics risks.

- Mitigations:

- Choose suppliers with ISO certifications and proven track records.

- Use third-party inspections to ensure consistent quality.

- Plan shipments to avoid tariff spikes and monitor supply chain risks.

- For small batches consider manufacturers offering flexible production runs and quick prototyping.

Choosing China for your sheet metal fabrication blends affordability with expertise in laser cutting sheet metal manufacturers, CNC stamping for metal parts, and cost-effective metal welding China facilities. With the right partner, you can confidently navigate challenges and benefit from China’s unmatched speed and scale.

Top Materials and Applications for China Sheet Metal Fabrication

Essential Materials Demystified

When it comes to sheet metal fabrication in China, knowing the right materials is key. The most common metals you’ll see are steel variants like stainless steel and carbon steel, aluminum, and copper. Each has its own strengths:

- Steel variants are sturdy and versatile. Stainless steel offers corrosion resistance, ideal for industries needing durability, while carbon steel is cost-effective for structural uses.

- Aluminum is lightweight, easy to work with, and excellent for applications where weight matters, like aerospace or automotive parts. Its natural corrosion resistance also adds value.

- Copper stands out in electronics for its excellent conductivity and malleability. It’s less common but essential in specific electrical components.

Across the board, suppliers in China are paying more attention to sustainability. You’ll often find recycled steel or aluminum options, which help reduce environmental impact without compromising quality.

Real World Applications Across Industries

China’s sheet metal fabrication serves a broad range of sectors. Here are some key places you’ll find these materials in action:

- Automotive: From body panels and brackets to EV battery enclosures, lightweight aluminum and precision steel parts are in high demand.

- Aerospace: High-grade aluminum alloys and stainless steel are used for aircraft frames, engine components, and safety parts.

- Electronics: Copper and thin stainless steel sheets are shaped into heat sinks, casings, and connectors.

- Construction: Steel sheets help build everything from support beams to decorative facades.

A good example is Vastpcc, a prominent fabricator specializing in EV components. They combine advanced processes with premium materials like aluminum and steel to build battery housings and chassis parts that meet the high standards of US automakers. This kind of expertise shows how Chinese sheet metal fabrication is not just cost-effective but also reliable for high-tech, demanding industries.

How to Select a Reliable Sheet Metal Fabricator in China

Choosing the right sheet metal fabricator in China can feel overwhelming, but focusing on a few key criteria makes the process smoother. Here’s what to look for when vetting suppliers:

Key Criteria for Vetting Suppliers

- Certifications: Look for ISO certifications like ISO 9001 for quality management. This ensures the supplier follows strict standards.

- Equipment and Capacity: Verify the factory’s machinery—laser cutting, CNC bending, stamping, welding—and their ability to handle your order volume, whether it’s low-volume sheet metal production or larger runs.

- Customer Reviews: Check feedback from other U.S. clients or global buyers. This helps gauge reliability and quality.

- Experience: Prioritize manufacturers with experience in your industry, such as automotive sheet metal components or electronics parts.

- Communication: Ensure clear, timely communication. Language or cultural gaps can cause delays and misunderstandings.

Overcoming Common Challenges

- Supply Chain Risks: Work with suppliers who can manage lead times and have contingency plans for raw material shortages or shipping delays.

- Cultural and Logistics Tips: Understand Chinese business culture—building a relationship can improve cooperation. Also, choose suppliers experienced in U.S. logistics and shipping.

- Tariffs and Trade Tools: Stay updated on tariffs affecting metal imports from China. Some fabricators offer tariff mitigation strategies or help with classification and documentation.

2025 Trends Shaping the Market

- Automation: More factories are adopting automation for laser cutting sheet metal manufacturers and CNC stamping services, improving speed and consistency.

- Sustainability: Eco-friendly materials and processes are gaining ground. Suppliers using recycled metals or energy-efficient methods score higher on sustainability.

- EV Demand Impact: The rise of electric vehicles boosts demand for precision metal bending services and custom sheet metal prototyping, especially for battery and chassis parts.

By focusing on these points, you can find a China sheet metal fabrication partner who offers quality, cost-effectiveness, and smooth project delivery, tailored perfectly for the U.S. market.

Spotlight on Vastpcc Your Partner for Custom Sheet Metal Excellence

Why Vastpcc Stands Out in China’s Landscape

With over 17 years of experience, Vastpcc has built a strong reputation in China’s sheet metal fabrication industry. Their fully integrated facility means they handle everything in-house—from design and prototyping to precision metal bending, laser cutting, CNC stamping, welding, and finishing. This end-to-end service helps ensure top quality, faster turnaround times, and competitive pricing that really benefits U.S. customers looking for cost-effective solutions without sacrificing reliability.

Working with global clients across various industries, Vastpcc understands the standards and expectations that come with international partnerships. They focus on on-time delivery and maintaining consistent quality, which makes them a dependable choice for custom sheet metal prototyping and manufacturing.

Success Stories and Client Wins

Vastpcc’s track record includes numerous projects for aerospace and automotive sectors where precision and quality are non-negotiable. For example, they’ve helped a leading aerospace supplier reduce lead times by 20% while maintaining strict ISO-certified quality standards. Another client in the automotive industry saw improved durability and fit of their sheet metal components thanks to Vastpcc’s expert CNC bending and welding services.

These anonymized cases highlight Vastpcc’s commitment to delivering results that meet the high demands of today’s market. If you’re after a China sheet metal fabrication partner known for exceptional turnaround and product quality, Vastpcc is worth considering.

Next Steps Get Your Custom Quote from Vastpcc Today

Ready to move forward with your China sheet metal fabrication needs? Vastpcc makes it simple to get started with a custom quote tailored to your project. Whether you need low-volume sheet metal production or precision metal bending services, Vastpcc offers competitive pricing, fast turnaround, and unmatched quality backed by 17+ years of experience.

Getting your quote is easy:

- Provide basic details about your project specifications

- Specify materials, quantities, and any special requirements

- Receive a clear, transparent quote with no hidden fees

Partnering with Vastpcc means you get an ISO-certified metal fabricator who understands the US market and its demands. From laser cutting to assembly and finishing, they cover all core processes with reliability and speed. Don’t let tariffs, shipping, or communication challenges slow you down—Vastpcc’s expertise in handling these ensures a smooth experience.

Contact Vastpcc today and see why so many US businesses trust them for cost-effective, high-quality sheet metal fabrication in China. Your next project deserves a partner who delivers on time and on budget.