Discover the exact titanium melting point, factors affecting it, and its industrial applications for aerospace medical and manufacturing uses.

If you’ve ever wondered why titanium melting point matters so much in industries like aerospace or medical manufacturing, you’re in the right place. Knowing the exact temperature at which titanium melts isn’t just trivia—it’s critical for engineers, metallurgists, and anyone handling this remarkable metal. In this post, we’ll cut through the noise and get straight to the facts, exploring what sets titanium apart, how its melting point influences performance, and why this knowledge could make all the difference in your next project. Let’s jump right in.

What is Melting Point

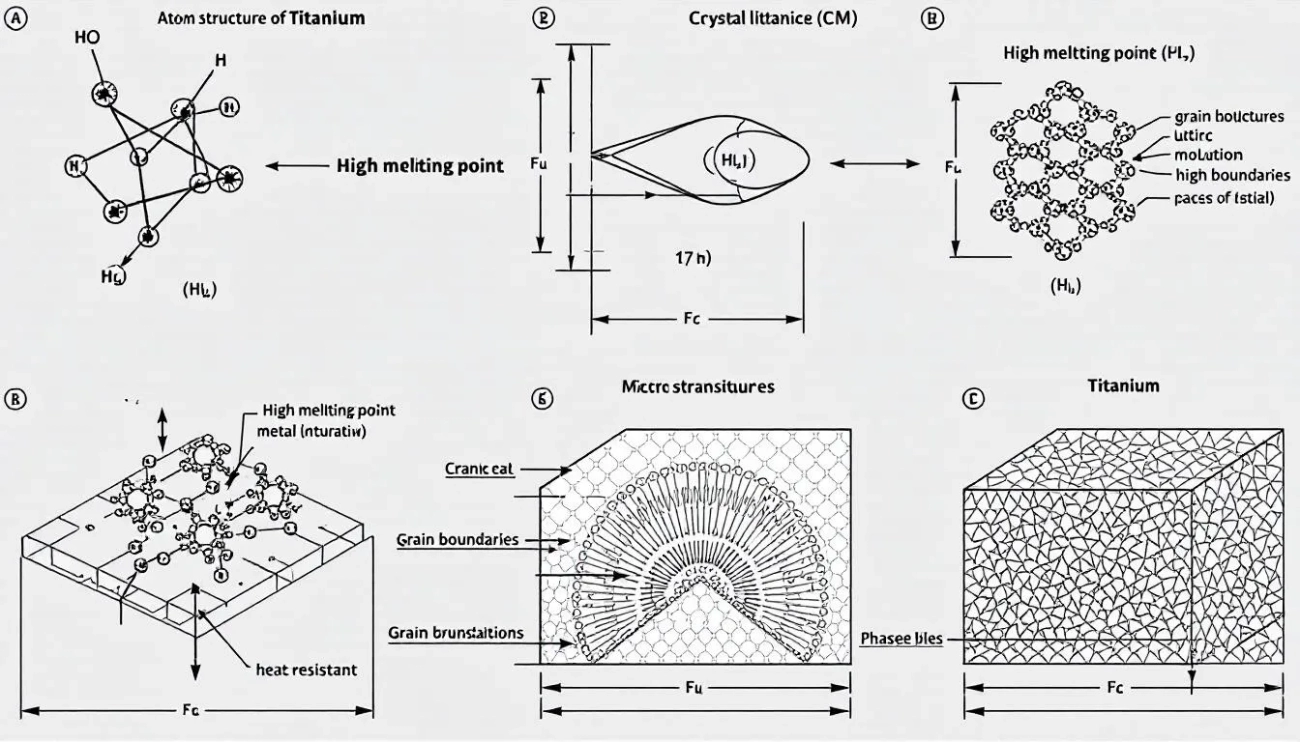

In materials science, the melting point is defined as the specific temperature at which a solid material changes into a liquid under standard atmospheric pressure. This phase transition occurs when the material’s internal atomic bonds break, allowing atoms or molecules to move freely. The melting point is a fundamental physical property that helps characterize and identify substances.

Understanding melting points is critical in metal processing and applications because it dictates how metals behave under heat. For metals like titanium, the melting point determines the suitable temperatures for casting, forging, welding, and heat treatment. It impacts manufacturing methods and ensures that components maintain structural integrity and performance during high-temperature exposure. Accurate knowledge of melting points helps engineers select appropriate materials for environments requiring thermal resistance and guides safe handling during metal processing.

Titanium Melting Point The Exact Value

The melting point of pure titanium is around 1,668 degrees Celsius (or 3,034 degrees Fahrenheit). In scientific terms, that’s about 1,941 Kelvin. This high melting temperature makes titanium stand out among common metals.

Across various scientific sources, you might see slight differences in this value—generally within a range of a few degrees Celsius. These variations come from factors like measurement methods or the titanium’s purity. But for most practical uses, 1,668°C is the solid reference point.

Knowing the melting point in these three units—Celsius, Fahrenheit, and Kelvin—helps professionals in the U.S. and globally when working with titanium in everything from manufacturing to research.

Factors Affecting Titanium’s Melting Point

Titanium’s melting point isn’t a fixed number—it changes depending on a few key factors. First, purity plays a big role. Commercially pure titanium melts at a specific temperature, but when you start mixing in other elements to make alloys, that value shifts. Alloying elements like aluminum, vanadium, or iron can raise or lower the melting point depending on their proportions and interactions.

Another important factor is titanium’s crystal structure. As titanium heats up, it undergoes phase changes—its atomic arrangement shifts between different crystal forms. These transformations happen at specific temperatures and can affect how the metal melts. For instance, the transition from the alpha phase to the beta phase near 1,130°C (2,066°F) has an impact on melting behavior.

Comparison Titanium vs Other Metals

When comparing melting points, titanium stands out among common metals used in U.S. industries. Here’s a quick look at typical melting points:

| Metal | Melting Point (°C) | Melting Point (°F) | Melting Point (K) |

|---|---|---|---|

| Aluminum | 660 | 1220 | 933 |

| Steel | ~1370–1530 | ~2500–2786 | ~1643–1803 |

| Nickel | 1455 | 2651 | 1728 |

| Titanium | 1668 | 3034 | 1941 |

Titanium’s melting point is significantly higher than aluminum and most steels, but slightly above nickel. This higher melting temperature means titanium performs better at elevated temperatures where other metals might soften or fail.

Why does this matter? In material selection, especially for sectors like aerospace or medical device manufacturing, titanium’s high melting point translates into:

- Better heat resistance in extreme environments

- Greater structural integrity under thermal stress

- Wider working temperature range before melting or deforming

Choosing titanium over aluminum or steel can mean longer-lasting parts when heat is involved. It also impacts processing methods, since titanium needs higher temperatures to melt or shape, influencing manufacturing choices in the U.S. market.

Industrial Implications of Titanium’s Melting Point

Titanium’s melting point plays a big role in several industries, especially in the U.S., where high-performance materials are in demand. Here’s how it impacts key sectors:

Aerospace applications:

Titanium’s high melting temperature (around 1,668°C or 3,034°F) makes it perfect for aircraft parts that face intense heat and stress. Its ability to hold strength at high temperatures means engines, airframes, and exhaust systems last longer and perform better without warping or melting.

Medical device manufacturing:

In medical gear like implants and surgical tools, titanium’s melting point ensures it can withstand sterilization processes that involve extreme heat. This durability is critical for safe, long-lasting medical devices.

Alloy production and heat treatment:

When producing titanium alloys, understanding the exact melting point helps control heat treatment. Careful heating improves strength, durability, and corrosion resistance. Precise temperature control avoids defects during alloy mixing, forging, or annealing.

Challenges in melting and casting titanium:

Titanium’s high melting point also brings some challenges. It requires special furnaces and protective atmospheres (like vacuum or argon gas) to prevent contamination during melting. Casting titanium is tricky because it solidifies quickly and can react with mold materials or gases, affecting quality and increasing costs.

Overall, the industrial uses for titanium rely heavily on managing its high melting point to unlock its great properties while dealing with the technical demands of processing it safely and efficiently.

How Titanium’s Melting Point Influences Its Properties

Titanium’s relatively high melting point plays a big role in its strength and durability. Because it can withstand extreme heat without losing its shape or breaking down, titanium is strong even in tough environments. This heat tolerance also helps titanium resist corrosion, making it ideal for use in harsh conditions like chemical processing or marine applications.

When it comes to manufacturing, titanium’s melting temperature affects the methods used to shape and join it. Forging and welding require careful control of heat to avoid damaging the metal or causing defects. In additive manufacturing (3D printing), titanium’s melting point demands precise temperature management to ensure each layer bonds properly without warping.

Safety and Handling Concerns at High Temperatures

Handling titanium near its melting point requires strict safety measures. Because titanium melts at around 3,034°F (1,668°C), working at these extreme temperatures can be risky if not done properly.

Safe melting and processing practices include:

- Use of specialized, high-temperature-resistant equipment designed for titanium’s heat range.

- Working in controlled environments with proper ventilation to avoid exposure to hazardous fumes.

- Employing inert gas atmospheres like argon to prevent titanium from reacting with oxygen or nitrogen, which can cause fires or contamination.

- Wearing heat-resistant gear to protect operators from burns and sparks.

- Regularly inspecting melting and casting systems to prevent equipment failure.

Potential hazards when reaching titanium’s melting temperature:

- Titanium is highly reactive at high temperatures and can ignite easily if exposed to oxygen.

- Molten titanium can cause serious burns and fires, which are difficult to extinguish.

- Improper cooling rates may lead to cracks or defects in the metal, compromising safety and quality.

- Exposure to fumes released during melting can pose health risks.

Following proper safety protocols ensures not only the quality of titanium products but also protects workers and facilities during high-temperature processing.

Latest Research and Technological Advances

Recent advances in titanium melting and processing focus on making the metal easier to work with at high temperatures. Researchers are developing new alloys and composites that adjust titanium’s melting point to better fit specific industrial needs. These innovations help improve performance in demanding environments like aerospace and medical fields.

Some breakthroughs include:

- Alloy design: Adding elements like aluminum and vanadium can change melting behavior and boost heat resistance without making the metal harder to melt.

- Improved melting methods: Techniques like vacuum arc remelting and electron beam melting reduce contamination and energy use during titanium casting.

- Advanced composites: Combining titanium with ceramics or carbon fibers creates materials that stay stable at higher temps and offer better strength-to-weight ratios.

- Additive manufacturing: 3D printing processes using titanium powders have become more refined, enabling precise control of melting and solidification to optimize part quality.

These developments not only help manufacturers meet tougher standards but also expand titanium’s role where heat tolerance and durability are crucial.