Discover the 6061 yield strength values by temper with detailed comparisons applications and factors for engineers and fabricators.

If you’re working with aluminum alloys, understanding 6061 yield strength isn’t just a nice-to-have—it’s essential. Whether you’re designing aerospace components, fabricating automotive parts, or prototyping with precision, knowing exactly when 6061 aluminum transitions from elastic stretch to permanent deformation can save your project from costly failures. In this post, we’ll cut through the jargon and deliver clear, actionable insights on 6061 yield strength across tempers like T6—plus the real-world factors that influence performance. Ready to make smarter material choices? Let’s dive in.

What is Aluminum 6061 A Quick Alloy Overview

Aluminum 6061 is one of the most widely used aluminum alloys in the United States and globally. Known for its excellent balance of strength, corrosion resistance, and machinability, 6061 finds use across diverse industries from aerospace to automotive. But what makes this alloy so popular?

Composition and History

6061 aluminum is part of the 6xxx series, which means its main alloying elements are magnesium and silicon. These components combine to form magnesium silicide, which helps strengthen the metal when heat-treated. The typical composition includes:

- Magnesium (Mg): 0.8% – 1.2%

- Silicon (Si): 0.4% – 0.8%

- Other elements: Small amounts of iron, copper, chromium, zinc, and titanium

Developed in the 1930s, 6061 quickly became a go-to alloy due to its versatile properties and ease of fabrication. Its adaptability through heat treatments has kept it a staple in engineering and manufacturing.

Key Non-Strength Properties

While yield strength is a critical factor, 6061 offers more than just mechanical performance:

- Corrosion resistance: Excellent in marine and industrial environments, especially when anodized.

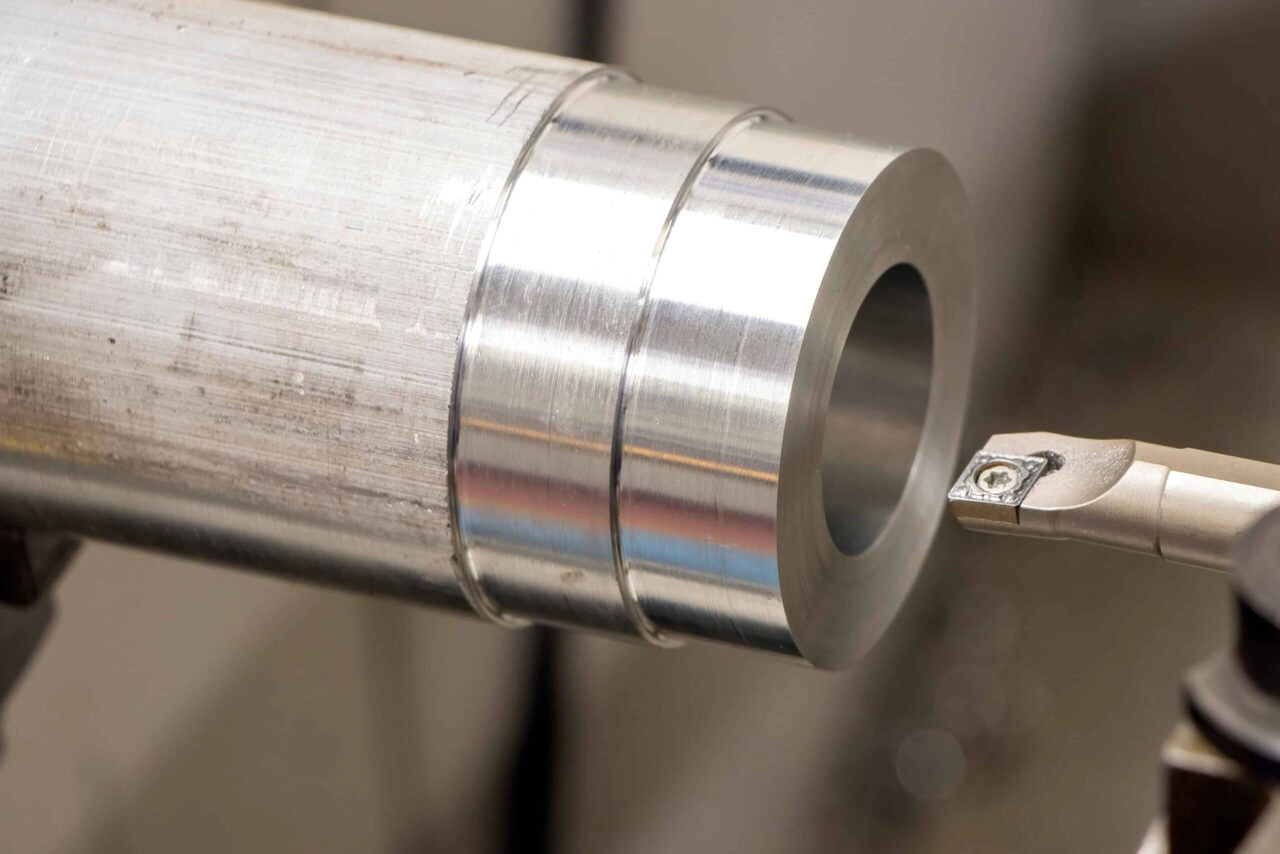

- Machinability: Easy to work with, making it a favorite for CNC machining and welding.

- Thermal conductivity: Good heat dissipation, useful in heat exchanger components.

- Surface finish: Smooth finish ideal for aesthetic and functional parts.

In short, 6061 aluminum balances strength with flexibility and durability, which explains why so many engineers rely on it as a starting point for design. Next, we’ll dive into the specific yield strength values this alloy offers across different tempers and standards.

Yield Strength of 6061 Aluminum Values by Temper and Measurement Standards

6061 aluminum’s yield strength varies significantly depending on its temper, which is just a way to describe the heat treatment and mechanical processing it’s gone through. The most common temper you’ll hear about is 6061-T6, which is heat-treated and artificially aged for maximum strength. Here are some typical yield strength values for popular tempers:

- 6061-O (annealed): Around 22,000 psi (150 MPa)

- 6061-T4 (naturally aged): About 35,000 psi (240 MPa)

- 6061-T6 (solution heat treated and artificially aged): Roughly 40,000 psi (276 MPa)

- 6061-T651 (T6 plus stress relief): Very close to T6, about 40,000 psi (276 MPa)

These values come from standardized tests like ASTM B209 and AMS 4037, which measure yield strength through tensile testing. The exact numbers can vary slightly based on factors like sample size, testing temperature, and equipment used.

Understanding temper is key—6061-T6 is far stronger than the annealed O temper, making it the go-to for structural and load-bearing applications. The T651 temper adds a stress relief step to prevent warping during fabrication, without sacrificing strength.

For a clear picture, imagine bending a 6061-O sheet will require far less force before it starts to deform permanently compared to a 6061-T6 sheet. This variance is why selecting the right temper is crucial depending on your project’s strength demands and fabrication process.

If you’re curious about how heat treatment affects yield strength in more detail or want to compare 6061 to similar alloys, we cover that next in the factors affecting strength section.

Factors Affecting 6061 Yield Strength From Heat Treatment to Environmental Stress

6061 aluminum’s yield strength can vary quite a bit depending on how it’s treated and where it’s used. One of the biggest factors is the heat treatment process. For example, the T6 temper involves solution heat treating followed by artificial aging, which boosts strength significantly. Skipping or changing these steps can drop yield strength noticeably.

Environmental factors also play a role. Higher temperatures tend to weaken 6061’s yield strength, so it’s not ideal for constant use in really hot conditions. On the other hand, cold environments don’t usually affect it much, which is good news for outdoor applications.

Welding is another important factor. Welding aluminum 6061 can reduce its yield strength in the heat-affected zones because the heat changes the metal’s microstructure. If strength is critical after welding, post-weld heat treatments might be necessary to restore some of the lost strength.

Fatigue and corrosion can also impact yield strength over time. Though 6061 has decent corrosion resistance, exposure to harsh environments without proper surface protection can lead to weakening. Fatigue from repeated loading should be accounted for in design, especially in critical parts.

Here are a few tips when testing or working with 6061 yield strength:

- Always check the after-treatment temper of your material.

- Consider environmental conditions during design.

- For welded parts, factor in strength loss or plan for post-weld treatments.

- Use corrosion-resistant coatings if the part will face harsh conditions.

- Perform fatigue testing if your design involves cyclic loads.

Understanding these factors helps ensure you get the performance you expect from 6061 aluminum in any application.

Comparing 6061 Yield Strength to Other Aluminum Alloys and Metals

When it comes to yield strength, 6061 aluminum stands out for its solid balance of strength, corrosion resistance, and workability. To put it in perspective, here’s a quick comparison of yield strengths for common materials used in manufacturing:

| Material | Typical Yield Strength (ksi) | Key Attributes |

|---|---|---|

| 6061-T6 Aluminum | 40–45 | Good strength, corrosion resistant, excellent machinability |

| 2024-T3 Aluminum | 50–55 | Higher strength, less corrosion resistant, commonly used in aerospace |

| 7075-T6 Aluminum | 70–83 | Very high strength, lower corrosion resistance, used in high-stress applications |

| 304 Stainless Steel | 30–40 | Moderate strength, excellent corrosion resistance, heavier than aluminum |

Use Cases and Engineering Insight

- 6061 aluminum is often the go-to for applications needing a good mix of strength and corrosion resistance without the cost and difficulty of working with top-tier alloys like 7075.

- 2024 and 7075 alloys serve better where maximum strength is the priority, such as aerospace components or structural parts under extreme forces.

- 304 stainless steel is favored when corrosion resistance and durability outweigh weight and machinability concerns, like in marine or food processing.

Regional Manufacturing Considerations

In the U.S., 6061 aluminum is widely produced and readily available with consistent quality certifications. Its popularity in automotive, aerospace, and marine sectors means local suppliers often stock multiple tempers and forms, reducing lead times and shipping costs. This accessibility makes 6061 a practical choice for nationwide manufacturers focusing on turning parts fast without sacrificing reliability.

Compared to harder-to-source alloys like 7075, 6061 also offers a smoother path for small-to-medium production runs — making it a staple in domestic machining shops, especially where ease of fabrication and supply reliability matter.

If you want to explore more about how 6061 compares technically and in usability, checking detailed specs on tensile strength 6061 and machinability 6061 alloy can offer deeper insights for your project needs.

Real-World Applications Where 6061 Yield Strength Shines

6061 aluminum’s yield strength makes it a top choice across many industries here in the U.S. Whether it’s aerospace, automotive, or marine, this alloy holds up well under stress while staying lightweight.

Industry Examples

- Aerospace: 6061’s balance of strength and weight helps in aircraft structural parts where reliability under load and fatigue resistance matter.

- Automotive: Used in frames, chassis components, and performance parts, it offers a solid yield strength that supports safety and durability.

- Marine: Its corrosion resistance combined with good yield strength makes it ideal for boat frames, masts, and other structural elements exposed to harsh environments.

Case Study on Cyclic Loads

In applications where parts undergo repeated stress, like aircraft wings or car suspensions, 6061-T6 performs reliably due to its fatigue strength. The alloy resists cracking and deformation under cyclic loads, making it a smart pick for components expected to last.

Design Tips and Safety Factors

- Always account for environmental conditions like temperature changes, which can slightly lower yield strength.

- Use a safety factor of 1.5 to 2 on yield strength for structural designs to ensure durability under unexpected loads.

- Consider tempering options: 6061-T6 offers higher yield strength than T4 or T651 but may be less forgiving under impact.

- Work with certified suppliers to get accurate data on the exact batch’s yield strength, as variations can occur depending on processing.

Using 6061 in designs where yield strength is critical lets you build lightweight, strong products with confidence, perfect for the demands of U.S. manufacturing and engineering standards.

Sourcing and Working with High-Yield 6061 Aluminum Expert Advice from VastPCC

When sourcing high-yield 6061 aluminum, working with a trusted supplier like VastPCC can make all the difference. We provide certified materials that meet industry standards, ensuring you get consistent quality every time. Our in-house testing checks yield strength, tensile strength, and other critical properties, so you can trust your aluminum performs exactly as expected.

Certification and In-House Testing

- Certified 6061 aluminum with detailed documentation

- Testing for yield strength, tensile strength, and corrosion resistance

- Consistent verification ensures reliable material performance

Machining and Fabrication Best Practices

6061 aluminum is known for its machinability, but to get the best results:

- Use sharp tools and proper speeds to avoid work hardening

- Coolants help reduce heat buildup during cutting or drilling

- Avoid overheating, which can reduce yield strength after heat treatment

- Plan welding carefully since it can affect strength and fatigue resistance

Local Sourcing Advantages

Choosing a local supplier like VastPCC offers multiple benefits for U.S. businesses:

- Faster turnaround times for orders

- Lower shipping costs and reduced delays

- Better communication and tailored customer service

- Access to expert advice on material choices and fabrication

If you’re looking to buy 6061 aluminum with high and reliable yield strength, contact VastPCC today. We’ll help you find the exact temper and dimensions that suit your project needs and keep your engineering designs strong and durable.