Discover expert tips and step-by-step guides on brass casting methods, alloys, safety, and applications for DIY and professional projects.

Understanding Brass Composition Properties and Why It Casts So Well

Brass casting works so well because of the unique properties of brass itself. At its core, brass is prized for its malleability, low melting point, corrosion resistance, and excellent acoustic and electrical conductivity. These qualities make it easier to melt and shape than many other metals while producing durable, attractive parts.

Brass typically consists of copper and zinc in varying proportions. Some common alloys include:

- C360 (leaded brass): Popular for its machinability, often used in precision fittings.

- C84400: Ideal for bushings and bearings due to good wear resistance.

- C693: A lead-free alloy that meets newer US regulations and supports eco-friendly projects, especially in plumbing.

To see how brass stacks up, consider this comparison table of brass versus bronze and aluminum brass:

| Property | Brass | Bronze | Aluminum Brass |

|---|---|---|---|

| Fluidity (castability) | High | Moderate | Superior |

| Corrosion Resistance | Good | Excellent | Excellent |

| Machinability | Excellent (C360) | Moderate | Good |

| Melting Point | Low (~1650°F) | Higher (~1800°F) | Lower (~1500°F) |

Aluminum brass stands out for its superior fluidity, making it perfect for capturing intricate details in casting.

In the United States, regulations increasingly favor lead-free brass alloys for plumbing fixtures and consumer products, supporting safer, greener manufacturing. Vastpcc leverages deep alloy expertise to tailor blends that optimize metal flow and minimize defects. Whether you need standard or custom brass alloys, contact us to ensure your project benefits from the best possible material performance and compliance.

Brass Casting Methods From Sand to Investment

Brass casting covers a range of methods, each suited for different projects and skill levels.

Sand Casting

This is a favorite for DIY and beginners. You can create patterns from simple materials like wood or styrofoam. Sand casting is affordable and flexible, making it great for small runs or larger parts with a rougher finish. The process involves making a sand mold around your pattern, then pouring molten brass into the cavity.

Investment Casting

For precision work like jewelry or detailed decorative pieces, investment casting is the way to go. It uses wax patterns that get coated in ceramic, then melted out, leaving a smooth mold. Techniques like centrifugal and vacuum casting improve accuracy and reduce defects, but setup is more complex and pricey compared to sand casting.

Continuous and Die Casting

Used mostly in industrial setups, these methods are designed for high-volume production. Continuous casting feeds molten brass through a mold in a steady stream, while die casting pushes brass into steel molds at high pressure. Both deliver consistent parts like plumbing fittings with tight tolerances but require expensive equipment.

Pros and Cons at a Glance

| Casting Method | Pros | Cons |

|---|---|---|

| Sand Casting | Low cost, simple patterns | Rough surface, less detail |

| Investment Casting | Smooth finish, fine detail | Higher cost, longer setup |

| Continuous Casting | High volume, consistent parts | Expensive equipment needed |

| Die Casting | Fast production, tight specs | Complex molds, high cost |

Basic Sand Casting Steps

- Make your pattern from wood or styrofoam

- Assemble the flask and pack it with fine sand around the pattern

- Remove the pattern, leaving a mold cavity

- Pour molten brass carefully into the mold

- Let it cool before breaking the sand to reveal your casting

For anyone starting out or looking to scale up, these brass casting methods offer options from simple DIY projects to industrial-level accuracy.

Step-by-Step Guide How to Cast Brass at Home or in the Shop

Casting brass yourself can be rewarding with the right prep and tools. Here’s what you need to know to get started safely and effectively.

Preparation and Tools

- Materials: You can use scrap plumbing fittings or brass ingots. Scrap is easier to source locally but may have impurities.

- Tools: A sturdy crucible, a reliable furnace or torch, heat-resistant gloves, and a respirator are crucial. Always protect yourself from zinc fumes released during melting.

Melting Brass

- Heat brass to around 1700°F to 1900°F.

- Use flux to reduce oxidation and keep the metal clean.

- Watch for common issues like porosity (tiny holes) and hot tears (cracks) — these often come from uneven cooling or poor alloy mix.

Molding and Pouring

- Design molds with proper draft angles to make removal easier.

- Remember to factor in shrinkage allowance — brass shrinks about 1%.

- Pour steadily and avoid splashing to reduce defects inside the casting.

Cooling and Finishing

- Let the brass cool gradually to avoid cracks.

- After cooling, anneal the piece to soften the metal for easier machining.

- Finish by machining and polishing for that signature gold-like sheen brass is known for.

Safety First

- Always wear PPE: gloves, eye protection, and a respirator.

- Work in a well-ventilated space to avoid inhaling zinc fumes.

- Keep a checklist handy to cover all safety measures.

DIY Project Example

Try casting a brass axe keychain. It’s a manageable size and lets you practice molding, pouring, and finishing all in one go.

Vastpcc Tip

If you want to scale up or ensure defect-free results, consider using foundry services like Vastpcc. Custom blends and expert handling make a big difference in quality and consistency.

Common Challenges in Brass Casting and How to Overcome Them

Brass casting comes with its share of challenges, but knowing how to handle them makes all the difference. Here are some common issues and practical solutions you can use, especially if you’re working on U.S.-based projects where environmental rules and quality matter.

Zinc Fuming

When melting brass, zinc fumes can be a big headache. These fumes are toxic and can cause health problems if not handled right. The solution? Use proper flux to reduce zinc oxidation and always have good ventilation or an exhaust system in place. A respirator is a must when working in smaller workshops or at home.

Shrinkage and Cracking

Brass shrinks as it cools, which can cause cracks or weak spots in your cast. Choosing the right alloy helps—some blends have better dimensional stability. Also, factor in appropriate shrinkage allowances in your mold design and control your cooling rate to avoid stress buildup.

Machinability Issues

Lead content improves machinability but comes with environmental and regulatory concerns, especially for plumbing parts in the U.S. Lead-free brass alloys like C693 offer a greener choice but may be harder to machine. It’s important to balance machinability with compliance, something Vastpcc can help you navigate with custom blends.

Quick Fix Table

| Problem | Cause | Vastpcc Solution |

|---|---|---|

| Zinc fumes | High zinc evaporation | Use flux and proper exhaust |

| Shrinkage cracks | Cooling stress | Use alloys with shrinkage control |

| Porosity | Gas entrapment | Optimize melting and mold design |

| Difficult machining | Lead-free blends | Custom alloy tuning |

FAQ Style Quick Tips

- Why do bubbles form in my brass casting?Gas trapped during pouring or poor mold venting. Improve venting and control melt cleanliness.

- How can I reduce porosity?Keep your melting temperature steady and avoid moisture in the mold.

- Is zinc fuming dangerous?Yes, always wear proper PPE and have ventilation.

By knowing these common pitfalls and how to address them, you can get better brass castings without headaches or compliance issues. At Vastpcc, we guide you through alloy choices and techniques to keep your projects running smooth and safe.

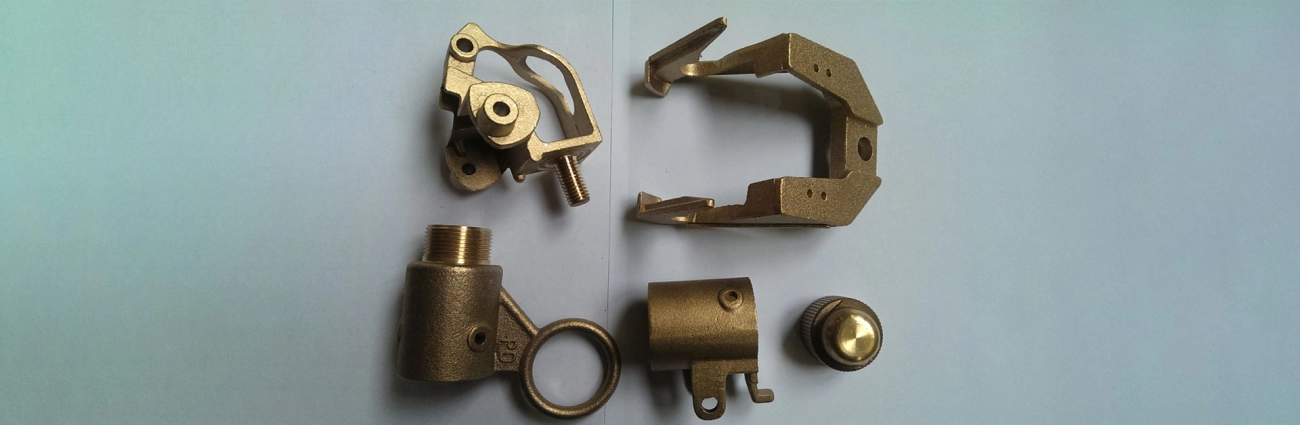

Applications and Industries Where Brass Casting Shines

Brass casting is incredibly versatile, making it a popular choice across many fields. On the DIY side, hobbyists and artists love using brass for sculptures, custom decor, and musical instruments because of its ease of casting and attractive finish. Brass captures fine details, which is perfect for unique, handcrafted pieces.

In industry, brass shines in manufacturing reliable valves, gears, and marine hardware where corrosion resistance is crucial. Its durability in harsh environments keeps parts working longer, especially around water or salty air. That’s why brass is a go-to in plumbing and marine applications.

A recent case study from Vastpcc highlights how precision brass bushings were produced for US manufacturers requiring tight tolerances and consistent quality. This shows brass casting’s strength in delivering high-performance, custom components for demanding industrial use.

Looking ahead, the market is shifting toward sustainable, lead-free brass alloys to meet stricter US regulations and green building standards. These eco-friendly options reduce environmental impact without sacrificing performance, making brass casting a smart, future-ready choice for both craftspeople and manufacturers.

For more on brass casting techniques and alloys, check out our detailed guides on [brass alloys for casting] and [investment casting brass].

Choosing a Brass Casting Partner Why Vastpcc Stands Out

When looking for a reliable brass casting partner in the US, Vastpcc offers top-notch services you can count on. Our state-of-the-art sand and investment casting facilities ensure precision and consistency from prototype to full production. We specialize in custom brass alloys tailored to your project needs, including lead-free options that meet stricter US regulations for plumbing and industrial parts.

What sets Vastpcc apart is our deep expertise in managing alloy flow and minimizing defects, which means your parts come out clean and ready to use. Whether you need small batches or large runs, we’re equipped to handle both with quick turnaround times.

Ready to start casting without hassle? Schedule your free consultation at vastpcc.com and get expert advice on materials, methods, and design to make your project a success.

Here’s what some of our clients say:

- “Vastpcc delivered flawless brass components exactly on time.”

- “Their custom alloy blends improved our product durability significantly.”

- “From prototype to production, they made the process smooth and easy.”

Partner with Vastpcc for quality brass casting you can trust.