Discover essential metal cutting techniques, tools, and safety tips for DIY projects with expert guidance on precision and efficiency.

Understanding the Basics of Metal Cutting Materials and Safety First

Metal cutting might sound straightforward, but there’s a lot beneath the surface. Getting to know the types of metals you’re working with and following safety protocols can save you from frustration and even injury.

Subtypes of Metals and Their Cutting Challenges

Different metals behave uniquely when cut. For example:

- Steel: Popular and strong, but harder steels require tougher blades or slower cutting speeds to avoid dulling tools.

- Aluminum: Softer and lighter, it can clog blades without proper lubrication or the right cutting method.

- Copper and Brass: These are softer metals that cut cleanly but may leave burrs needing extra finishing.

- Stainless Steel: Tough and resistant to heat, it demands blades designed for high-strength metals and careful feed rates.

- Sheet Metal: Thin and flexible, it bends or warps easily if not supported correctly during cutting.

Essential Safety Protocols and Common Hazards

Metal cutting isn’t without risks. Here’s what you should keep in mind:

- Always wear safety glasses and cut-resistant gloves.

- Use hearing protection, especially with power tools like angle grinders or saws.

- Beware of hot sparks and sharp edges—keep a fire extinguisher nearby and work in a clear, ventilated space.

- Secure your metal pieces firmly to avoid shifts during cutting.

- Avoid loose clothing or jewelry that can get caught in tools.

Quick-Reference Table Metal Types and Ideal Cutting Methods

| Metal Type | Ideal Cutting Method |

|---|---|

| Steel | Band saw, plasma cutter, angle grinder |

| Aluminum | Circular saw with carbide blade, laser cutting |

| Copper/Brass | Tin snips, shears, laser cutting |

| Stainless Steel | Oxy-fuel torch, plasma cutter, waterjet |

| Sheet Metal | Aviation shears, snips, laser cutting |

How Vastpcc’s Precision Services Complement DIY for Complex Jobs

Sometimes the DIY route reaches its limits. That’s where Vastpcc steps in. Their expert precision cutting handles tough materials, intricate shapes, and high-volume projects you can’t tackle at home. Using Vastpcc alongside your own work ensures professional results without investing in expensive equipment. So, why struggle with precision cuts when you can focus on assembly and finishing, letting the pros handle the complex metal cutting?

Understanding these basics sets you up for successful and safe metal cutting every time. Ready to roll up your sleeves? Let’s explore cutting methods next.

Top Metal Cutting Methods From Manual to High-Tech

When it comes to metal cutting, choosing the right method depends on your budget, skill level, and the type of metal you’re working with. Here’s a quick rundown of popular techniques—from simple hand tools to advanced tech.

Manual Techniques for Beginners

If you’re just starting out or working on a tight budget, manual tools are your best bet. These include:

- Hacksaw: Great for straight cuts on pipes, rods, or sheet metal. It’s affordable and easy to control but can take time on tougher metals.

- Cold Chisel: Perfect for cutting or shaping metal without heat, especially useful for trimming or making small adjustments.

- Tin Snips: Ideal for cutting thinner sheet metals like aluminum or galvanized steel. They come in straight, left, and right cutting versions.

- Aviation Shears: Provide more leverage and cleaner cuts on sheet metal compared to tin snips, especially good for curves and precision cuts.

Power Tool Essentials

Stepping up to power tools speeds things up and gives you cleaner edges. Common choices include:

- Reciprocating Saw: Versatile for cutting pipes, metal sheets, and even bolts. It’s portable but can leave rough edges depending on the blade.

- Angle Grinder: A go-to for grinding, cutting, and polishing metal. Right blade choice is crucial—cutoff wheels are great for thin metals; diamond blades handle tougher jobs.

- Band Saw: Offers smooth, straight cuts on thick metal bars or rods. Ideal for precision work and longer cuts.

- Chop Saw: Best for quick, straight cuts on metal pipes and bars. Often used in fabrication shops for repetitive cuts.

Each of these tools comes with different blade options and speeds, so picking the right one affects cut quality and safety.

Advanced Cutting Options

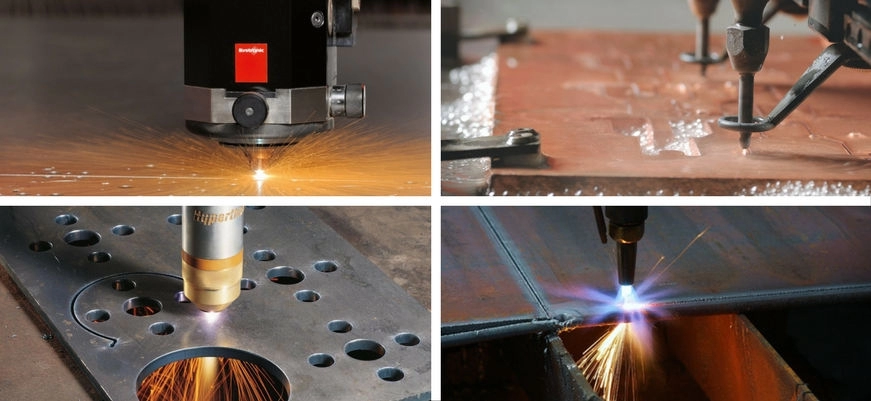

For high-precision or heavy-duty jobs, more advanced methods come into play:

- Plasma Cutters: Use an ionized gas jet to slice through thick metals fast and cleanly. Great for complex shapes and heavy materials.

- Oxy-Fuel Torches: Classic method for cutting thick steel pipes or structural pieces. Requires safety know-how and proper ventilation.

- Laser Cutting: Perfect for ultra-precise, intricate cuts on sheet metal. Usually outsourced due to costly equipment.

- Waterjet Cutting: Uses high-pressure water and abrasive to cut metals without heat distortion. Ideal for delicate or heat-sensitive materials.

Outsourcing Overview

Not every job needs to be done at home. For difficult or super precise cuts, outsourcing to specialists (like Vastpcc’s cutting services) is often the best choice. They handle complex shapes, tough steels, and guarantee smooth, burr-free edges without the hassle.

Cut Quality and Speed Infographic

To help you choose, here’s a quick comparison of common metal cutting methods by cut quality and speed:

| Method | Cut Quality | Speed | Best For |

|---|---|---|---|

| Hacksaw | Moderate | Slow | Small DIY cuts on thin metals |

| Tin Snips / Shears | Good (thin metal) | Moderate | Sheet metal fabrication |

| Reciprocating Saw | Rough to Good | Fast | Pipes, demolition work |

| Angle Grinder | Good | Fast | Versatile, multipurpose |

| Band Saw | Very Good | Moderate | Precision cuts in bars/rods |

| Chop Saw | Good | Very Fast | Straight cuts in pipes/bars |

| Plasma Cutter | Excellent | Very Fast | Thick metal, custom shapes |

| Oxy-Fuel Torch | Good | Fast | Heavy steel, structural cuts |

| Laser Cutting | Excellent | Fast | Detailed sheet metal parts |

| Waterjet Cutting | Excellent | Moderate | Heat-sensitive metals |

Picking the right method means balancing your project budget, skill level, and the metal type. For reliable, quality cuts on tougher metals, Vastpcc’s precision services can be a valuable partner to your DIY efforts.

Choosing the Right Metal Cutting Tools Buyers Guide

Picking the right metal cutting tools depends on your budget and the type of projects you take on. Here’s a quick budget breakdown to help you shop smart:

- Under $50: Manual tools like hacksaws, tin snips, and cold chisels are affordable and great for simple cuts.

- $50 to $150: Basic power tools such as cordless multi-tools or angle grinders fit this range, offering more speed and precision.

- $150 and up: Advanced cordless multi-tools, band saws, and portable plasma cutters give you professional-quality cuts, perfect for serious DIYers or small shops.

Brand Spotlights

- Milwaukee: Known for durability and powerful cordless multi-tools. Great for heavy-duty metal pipe cutting and precision jobs.

- Evolution: Budget-friendly with versatile blades that cut through various metals cleanly.

- DeWalt: Trusted for reliable angle grinders and saws, often praised for long battery life and ease of use.

Must-Have Accessories

- Blades: Use the right blade for your material—bi-metal blades for tougher metals and carbide-tipped for sheet metal fabrication.

- Lubricants: Cut smoother and keep blades cooler by applying lubricants like cutting oil.

- Deburring Tools: Essential for removing sharp edges and burrs, ensuring safe, clean finishes.

Pro Maintenance Tips

- Clean blades after every use to prevent rust.

- Sharpen or replace blades regularly for the best cut quality.

- Keep power tools charged and inspect cords for damage.

- Store tools in a dry place to extend their lifespan.

For precise, hassle-free metal cutting beyond DIY, Vastpcc offers custom cutting services tailored to your exact needs. Check out their catalog to save time and get professional results on your toughest jobs.

Step-by-Step Tutorials Real-World Metal Cutting Projects

Project 1 Cutting Metal Pipe for Plumbing with Reciprocating Saw

- Measure and Mark – Use a tape measure and marker to get exact pipe length.

- Secure the Pipe – Clamp the pipe tightly to avoid movement during cutting.

- Choose the Right Blade – Use a metal cutting blade designed for reciprocating saws.

- Cut Slowly and Steadily – Let the saw do the work; avoid forcing the blade.

- Deburr the Edges – Use a file or deburring tool to smooth rough edges.

Project 2 Shaping Sheet Metal Brackets with Shears and Grinder

- Cut Sheet Metal with Aviation Shears or Tin Snips – Follow marked lines carefully.

- Smooth Cuts Using an Angle Grinder – Attach a flap disk to clean edges.

- Troubleshooting Common Issues

- Problem: Jagged edges

Solution: Use finer grit discs and slow grinder movement. - Problem: Warping metal

Solution: Cut in smaller sections to relieve stress.

- Problem: Jagged edges

Project 3 Precision Rod Trimming Using Band Saw

- Measure Twice, Cut Once – Mark cutting points precisely.

- Set Band Saw Blade Tension Correctly – Check before each cut.

- Use a Jig or Guide – Keeps rod steady and ensures straight cuts.

- Maintain a Slow Feed Rate – Prevents overheating and blade damage.

- Check Cut Quality and Deburr – File any burrs left behind for a clean finish.

Common Pitfalls and Solutions

- Overheating – Use cutting lubricants or pause to cool blade.

- Uneven Edges – Check blade sharpness and alignment regularly.

- Blade Binding – Don’t rush cuts; keep steady pressure.

Enhancing the Learning with SEO-Friendly Content

- Embedded videos show each project step clearly.

- Alt-text images demonstrate tools and techniques up close.

- Clear instructions improve accessibility and help beginners follow along easily.

These simple tutorials cover key metal cutting skills useful for home workshops across the US. For tougher jobs, Vastpcc’s custom metal cutting services can step in with precision and speed when you need it most.

Advanced Tips and Troubleshooting Elevate Your Metal Cutting Game

To get the best results when metal cutting, focus on optimizing feed rates, coolant use, and cutting angles. Going too fast can cause rough edges or tool damage, while going too slow wastes time. Use coolant or cutting oil to reduce heat buildup and prevent warping, especially when working with thicker metals. Adjust your cutting angle based on the tool and metal type for cleaner, smoother cuts.

Eco-Friendly Home Shop Practices

Keep your workspace safe and green by minimizing metal waste and sparks. Use scrap metal efficiently or recycle scraps instead of tossing them. Clear chips and dust regularly to avoid fire hazards. Using water-based coolants or lubricants can reduce fumes and environmental impact. Wear protective gear like goggles and gloves to stay safe.

When to Outsource for High Precision

Some jobs call for expert help. If you need ultra-precise cuts, complex shapes, or hard-to-cut metals, it’s smart to scale up by outsourcing. Companies like Vastpcc offer precision metal cutting services that handle plasma cutting, laser, and waterjet with exacting detail. This saves time, reduces waste, and ensures professional-quality results.

Future Trends in Metal Cutting

The metal cutting world is moving fast. Portable cordless tools are making it easier to work on the go without losing power or precision. Plus, additive manufacturing (3D printing metals) is starting to blend with traditional cutting, opening new doors for custom fabrication and repair. Staying updated with these trends keeps your metal cutting skills sharp and ready for anything.