Discover what temperature steel melts at ranging from 1370 to 1530°C with expert insights on steel types and heat factors.

If you’ve ever wondered what temperature does steel melt or why that number isn’t just one fixed point, you’re not alone. Whether you’re a hobbyist blacksmith, an engineer, or just curious about metal properties, knowing steel’s melting range is crucial—and it’s more complex than you might think. Steel doesn’t just melt at a single temperature; it varies between about 1370°C and 1530°C (2500°F to 2800°F) depending on its alloy makeup and other factors.

In this guide, you’ll get a clear, straightforward answer upfront—plus the insider details on why that range exists, how different steels behave under heat, and what that means for your projects. Ready to unlock the facts and get confident working with steel? Let’s dive in.

Understanding the Basics What Is Steel and Why Does It Melt

Steel is an alloy primarily made of iron and carbon, sometimes mixed with other elements like manganese, chromium, or nickel to enhance its properties. It’s one of the most widely used materials because of its strength, durability, and versatility.

When we talk about steel melting, we’re referring to the temperature at which it changes from a solid to a liquid. This melting point isn’t fixed—it depends on the exact composition of the steel. The more alloying elements it has, the more the melting temperature can vary.

At VastPCC, we understand steel’s thermal behavior deeply because working with steel at high temperatures is common in industries like construction, manufacturing, and metalworking. Knowing the basics of steel’s melting helps us deliver solutions that match your real-world challenges—whether you’re welding, forging, or recycling steel.

The Melting Point of Steel Breaking Down the Range

General Range and Variations

Steel doesn’t have a single melting point because it’s a mixture of iron and other elements. For most steels, the melting point ranges between 2,500°F and 2,800°F (about 1,370°C to 1,540°C). This range varies depending on the steel’s composition, especially the amount of carbon and other alloying metals.

Temperature Thresholds Table

| Type of Steel | Approximate Melting Point (°F) | Approximate Melting Point (°C) |

|---|---|---|

| Carbon Steel | 2,500 – 2,800 | 1,370 – 1,540 |

| Stainless Steel | 2,500 – 2,750 | 1,370 – 1,510 |

| Tool Steel | 2,650 – 2,800 | 1,460 – 1,540 |

These numbers are rough estimates since exact melting points rely on the steel’s specific makeup and heat treatment.

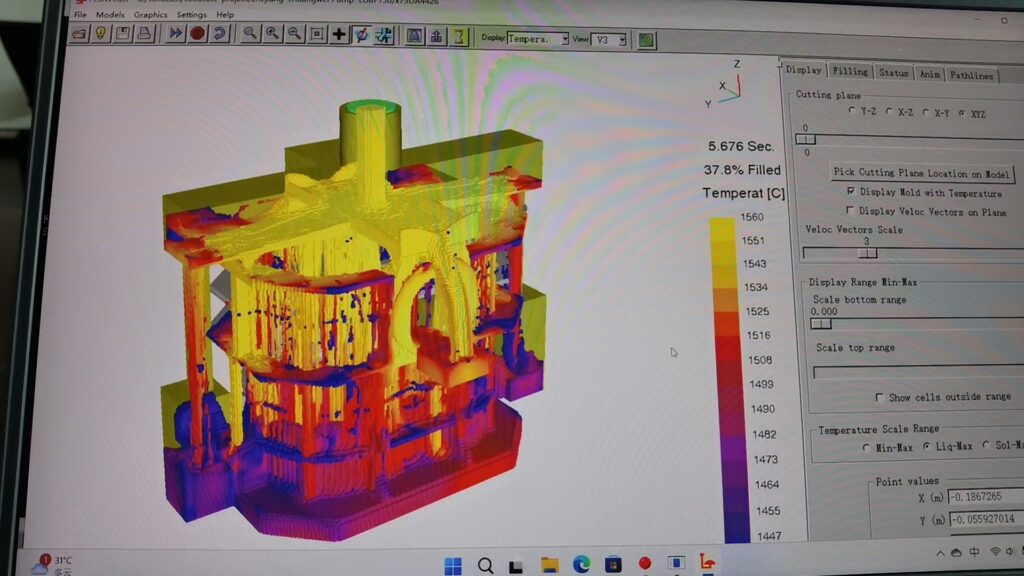

Measurement Methods

Steel melting points are determined using different techniques like:

- Differential Scanning Calorimetry (DSC): Measures heat flow as steel is heated.

- Thermocouples: Track temperature during controlled heating.

- High-temperature furnaces: Practical tests to observe when steel becomes molten.

Common Myths Busted

- Myth: All steel melts at exactly 2,800°F.Reality: Melting varies due to alloy content and impurities.

- Myth: Steel instantly melts at its melting point.Reality: Steel softens before reaching full liquid state; it goes through a plastic, mushy phase first.

- Myth: Stainless steel melts at a lower temperature than carbon steel.Reality: Stainless steel’s melting range can overlap or sometimes be higher depending on the alloy.

Understanding these points helps avoid confusion when working with steel in different applications or temperatures.

Types of Steel and Their Specific Melting Points

Steel comes in different forms, and each type melts at its own temperature range. Knowing the specific melting point helps in choosing the right steel for your project, especially if heat is involved.

Carbon Steel

Carbon steel is one of the most common steels. Its melting point generally falls between 2,500°F and 2,800°F (1,370°C to 1,540°C). The exact temperature depends on the amount of carbon and other elements mixed in. More carbon usually lowers the melting point slightly.

Stainless Steel

Stainless steel melts a bit higher due to its chromium and nickel content. It usually melts around 2,500°F to 2,750°F (1,370°C to 1,510°C). The extra metals help it resist corrosion and also influence its “fusion point.”

Tool and Alloy Steels

Tool and alloy steels contain various elements like tungsten, molybdenum, or vanadium. These make the steel tougher and increase its melting point. Their melting points vary widely but often range from 2,500°F up to 3,000°F (1,370°C to 1,650°C) or more. These are used in high-temperature environments where strength is key.

Comparison Infographic

To make it easy, here’s a quick look at melting ranges in Fahrenheit:

| Steel Type | Melting Range (°F) |

|---|---|

| Carbon Steel | 2,500 – 2,800 |

| Stainless Steel | 2,500 – 2,750 |

| Tool and Alloy | 2,500 – 3,000+ |

VastPCC Expertise

At VastPCC, we know these temperature ranges matter when you’re working with steel. Whether you’re forging, welding, or just planning a project, understanding these differences helps you avoid mistakes and choose the right materials for your needs.

Factors Influencing Steels Melting Temperature

Alloying Elements

One of the biggest factors that affect the steel melting point is its alloying elements. Steel isn’t just iron—it often includes carbon, chromium, nickel, manganese, and other metals. Each of these elements changes the melting temperature. For example, adding carbon generally lowers the melting point a bit, while elements like chromium and nickel can increase it. That’s why carbon steel melts at a different temperature than stainless steel or tool steels.

External Variables

Besides the steel’s makeup, external factors also play a role. Pressure, heating rate, and even the atmosphere around the steel can impact when it actually melts. For instance, higher pressure tends to raise the melting point, while impurities or contaminants can cause it to vary. How the steel is heated—slowly or quickly—can also influence the melting process.

Real-World Case Study

To put this into perspective, consider a steel forge in a U.S. manufacturing plant. Operators found that stainless steel parts required heating to around 2600°F to properly soften and reshape. Meanwhile, carbon steel parts started to melt closer to 2500°F. Knowing these subtle differences helped optimize their heating cycles, reduce waste, and improve product quality. This real-world example highlights why understanding the factors behind steel’s melting point isn’t just academic—it’s practical for anyone working with metals.

Practical Implications Heat Behavior Before Melting

Before steel actually melts, it goes through important changes that affect how it behaves. As steel heats up, it starts to soften and lose strength. This is crucial to understand if you’re working with steel in construction, manufacturing, or repair. Softened steel can bend or deform, so knowing these heat zones helps prevent damage.

Softening and Strength Loss

- Steel begins to weaken around 1,100°F to 1,500°F, depending on the type.

- It won’t hold its shape as well, making it easier to mold but also easier to damage.

- Extreme heat close to melting causes the metal to become brittle and prone to cracking.

Applications in Industry

- Steel forging depends on heating within the softening range to shape metal.

- Welding requires temperatures near melting without reaching full melt.

- Heat treatment processes use controlled heating and cooling to improve steel’s toughness and hardness.

Safety Tips

- Always wear heat-resistant gloves and eye protection when working near hot steel.

- Use proper ventilation to avoid harmful fumes during heating.

- Avoid sudden cooling (like water quenching) near melting temperature to prevent cracks and warping.

VastPCC Tip

Keep temperature gauges handy and monitor steel closely when heating. Stop before you hit the melt point to keep your work safe and the steel’s strength intact. This simple step saves time, money, and prevents accidents on the job.

How to Work with Steel at High Temperatures

Techniques Overview

When working with steel at high temperatures, it’s important to use the right heating methods. Common techniques include forge heating, induction heating, and torch heating. Each method heats steel differently but aims to make it easier to shape or weld without damaging its structure. It’s crucial to control the temperature precisely to avoid overheating or softening steel too much before its melting point.

Equipment Essentials

Having the right gear is a must. Here’s what you’ll typically need:

- High-temperature furnace or forge for consistent heat

- Protective gloves and eye gear to stay safe from sparks and heat

- Temperature gauges or infrared thermometers to monitor heat accurately

- Anvils, hammers, and tongs designed for hot steel handling

- Proper ventilation is key to avoid buildup of harmful fumes

DIY vs Pro Advice

If you’re a DIY enthusiast, stick to small-scale heating tools like handheld torches and always follow safety guidelines. Avoid guessing temperatures—use a proper thermometer. For professional work, it’s best to invest in advanced heating systems and get training to handle steel’s thermal properties correctly. Overheating or fast changes in temperature can cause cracks or weaken the steel, so precise control is everything in a pro setting.

By understanding these techniques and tools, you can safely and efficiently work with steel at high temperatures whether you’re fixing something yourself or doing professional metalwork.