Advanced Casting Technologies & Precision Machining Solutions

Integrating silica sol gel, precision casting, and additive manufacturing to deliver high performance critical components.

About VastPCC

Our Journey & Development History

VastPCC has evolved through years of innovation and dedication, specializing in advanced manufacturing technologies. Our expertise spans silica sol gel processes, precision casting, machining, and surface treatments, enabling us to deliver superior quality components.

Core Business & Technologies

- Silica Sol Gel Technology for high-performance molds

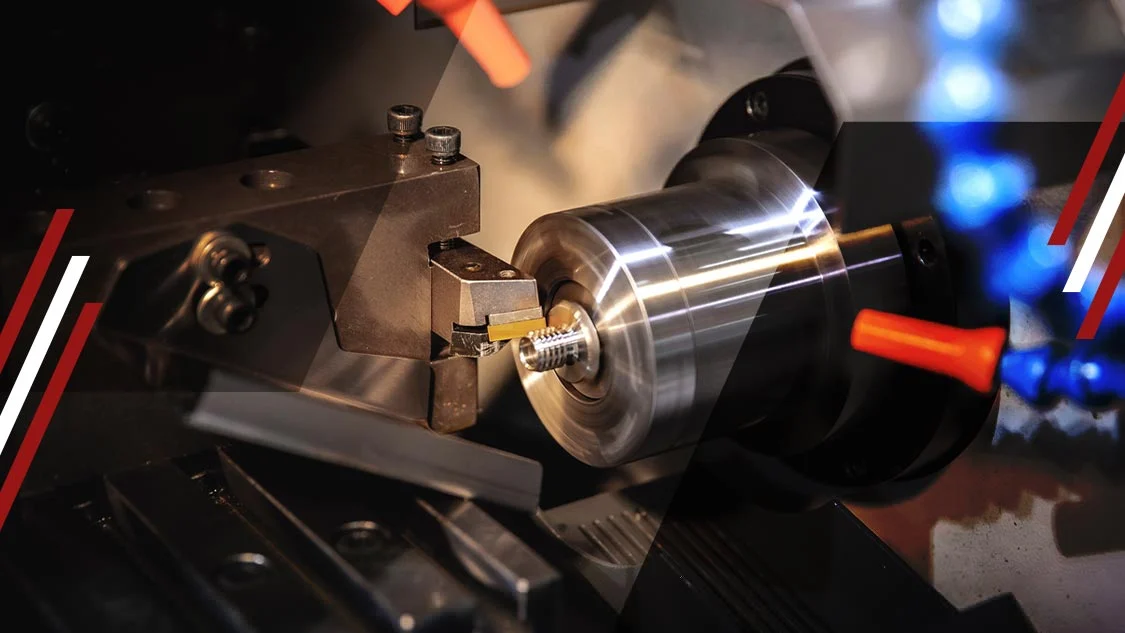

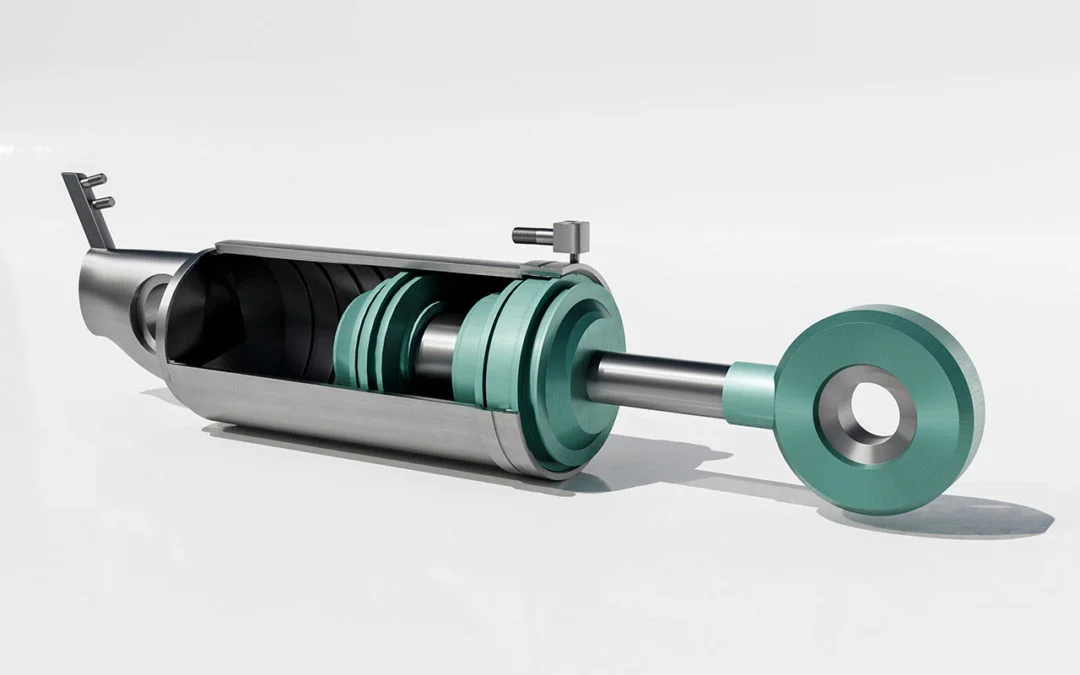

- Precision Casting ensuring dimensional accuracy

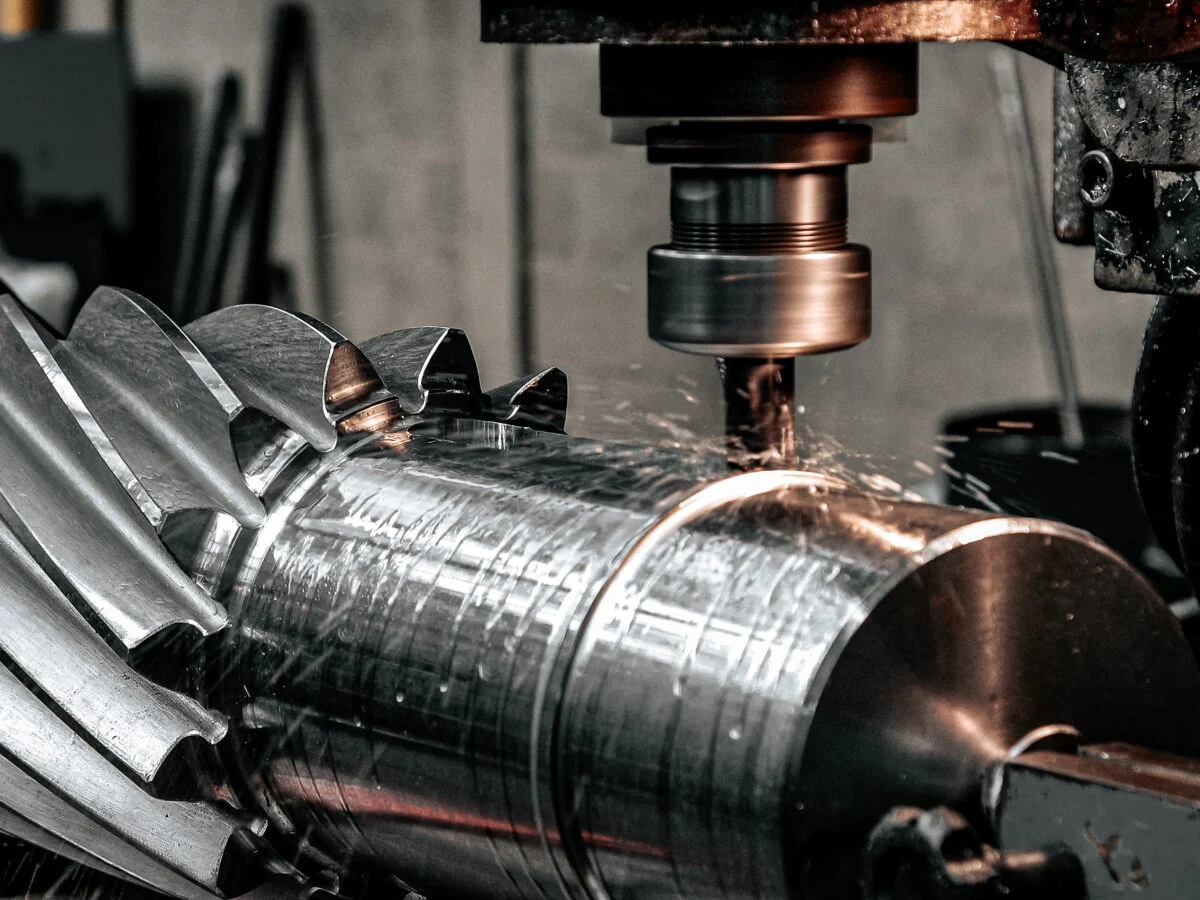

- Advanced Precision Machining for complex parts

- Surface Treatment Technologies enhancing durability

Production Scale

Our state-of-the-art facilities enable a monthly output of 1.3 million parts, meeting the demands of diverse industries with consistent quality and reliability.

Learn More

Core Technologies Overview

Silica Sol Gel Precision Casting

Explore the detailed process of silica sol gel precision casting, offering exceptional dimensional accuracy and surface finish. This technique enables complex geometries with minimal defects.

Technical Benefits

- High precision and repeatability

- Excellent surface quality

- Reduced material waste

- Compatibility with heat resistant steels and alloys

Typical Applications

Used in aerospace, automotive, and tooling industries where complex, high-strength components are required.

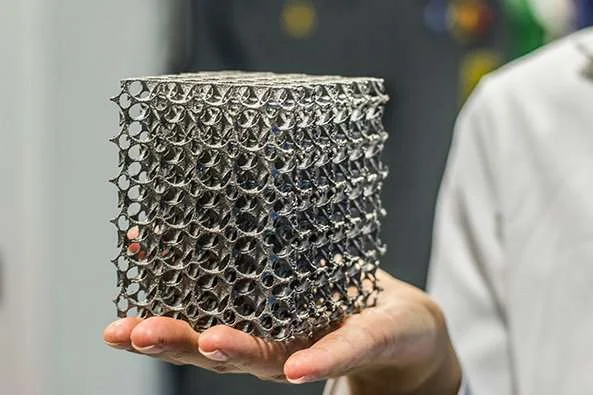

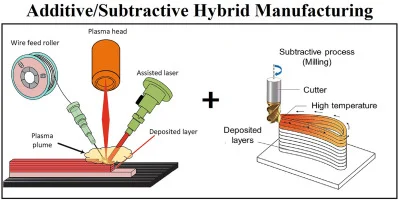

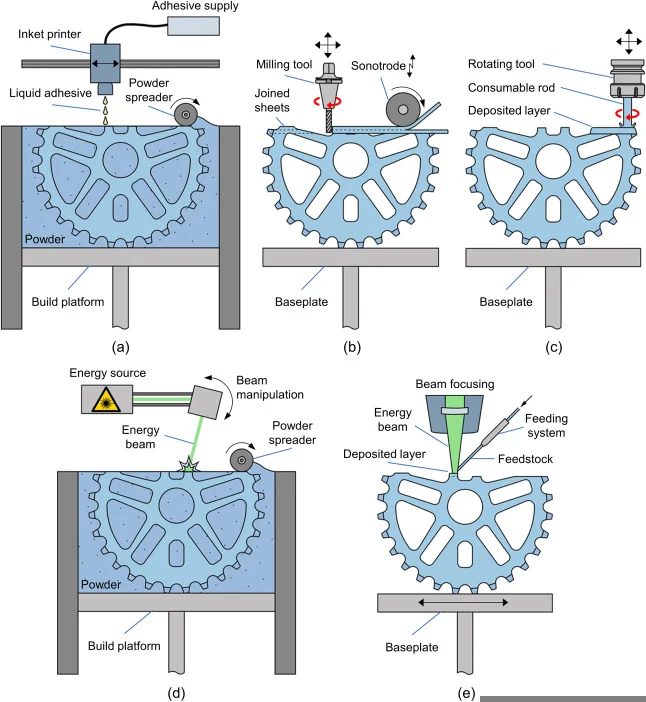

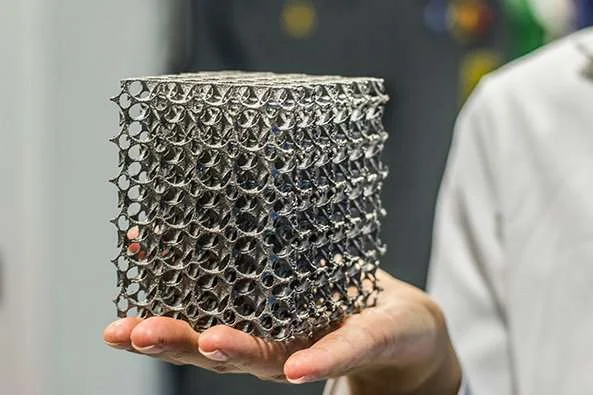

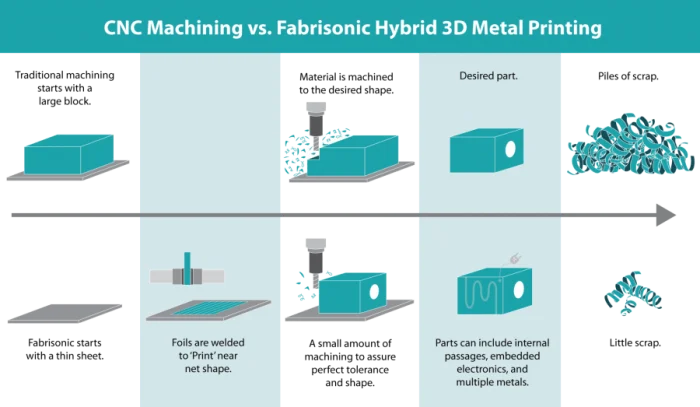

Additive Manufacturing Integration

Combining additive manufacturing with traditional casting creates synergy for innovative solutions, enabling rapid prototyping and complex part production.

Advantages

- Reduced lead times

- Design freedom for complex geometries

- Cost-effective small batch production

- Enhanced material properties through hybrid processes

Surface Treatment Technologies

Advanced surface strengthening and treatment methods improve corrosion resistance and durability of heat resistant steels and alloy materials.

Key Features

- Enhanced corrosion and wear resistance

- Improved thermal stability

- Extended component lifespan

- Compatibility with various alloy compositions

Product Applications & Industries Served

Aerospace & Gas Turbines

High-performance components engineered for extreme conditions in aerospace and gas turbine applications, ensuring reliability and efficiency.

Nuclear Power

Components designed to meet stringent safety and operational standards for nuclear power plants, optimized for durability in harsh environments.

Marine Engineering

Robust and corrosion-resistant solutions tailored for marine engineering, supporting operational excellence in challenging sea environments.

Technical Specifications

- Operating temperature range: -50°C to 1200°C

- Corrosion resistance: ASTM B117 certified

- Material composition: High-grade alloys and composites

- Compliance: ISO 9001 & AS9100 standards

Operational Environment Suitability

- Extreme temperature fluctuations

- High-pressure and vibration resistance

- Saltwater and chemical exposure protection

- Long lifecycle with minimal maintenance

Visual Aids & Industry Icons

Detailed diagrams and icons illustrate product integration across aerospace, nuclear, and marine sectors for clear understanding.

VastPCC Technical Strength & Strategic Partnerships

Cutting-Edge R&D & Technology Reserves

VastPCC leverages advanced research and development capabilities to maintain a robust technology reserve. Our innovation pipeline is fueled by continuous investment in state-of-the-art manufacturing technologies and materials science.

Strategic Collaborations with Industry Leaders

We proudly partner with renowned institutions such as China Steel Research Institute and Xi’an Aero Engine Group. These collaborations accelerate innovation and ensure our solutions meet the highest industry standards.

Innovation Achievements & Certifications

Our commitment to excellence is demonstrated by numerous technical certifications and breakthrough achievements in manufacturing processes, quality control, and product performance.

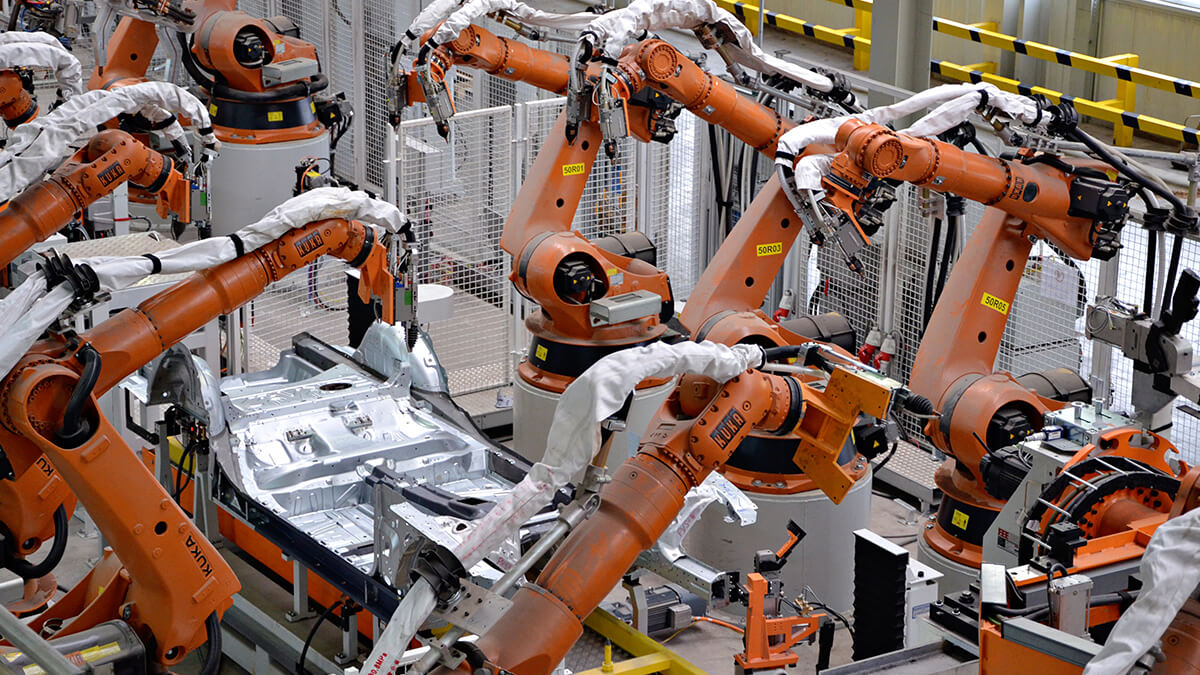

Production Facilities & Equipment

At VastPCC, our Qingdao Dongying production bases are equipped with state-of-the-art machinery and modern equipment investments to ensure superior production capacity and rigorous quality control systems.

Modern Equipment Investments

We continuously invest in cutting-edge machinery to enhance efficiency and precision across all production lines.

Production Capacity

Our facilities are designed to handle large-scale production demands while maintaining flexibility for custom orders.

Quality Control Systems

Rigorous quality assurance protocols ensure every product meets VastPCC’s high standards before delivery.

Success Stories & Case Studies

Milestone Achievements in Industry 4.0

VastPCC revolutionized manufacturing by integrating Industry 4.0 technologies, achieving a 40% increase in production efficiency for a leading client.

Technical Challenges & Innovative Solutions

Overcoming complex part manufacturing challenges, VastPCC developed custom tooling and processes that reduced defects by 30% for a major aerospace client.

Innovative Problem Solving with Additive Manufacturing

Leveraging additive manufacturing, VastPCC enabled rapid prototyping and reduced lead times by 50%, empowering clients to accelerate product development cycles.