Precision Casting Solutions for Marine Engineering

Durable Metal Components Customized for Marine Equipment and Offshore Applications

About VastPCC Marine Engineering Division

Established in 2003, VastPCC has specialized in high-difficulty precision casting and machining. Our production facilities in Qingdao and Dongying achieve a monthly output of 1.3 million pieces.

We focus on meeting rigorous standards for marine engineering and offshore equipment, exporting products to over 40 countries worldwide.

About Us

Precision Casting

Advanced casting techniques ensuring high strength and corrosion resistance for marine alloys.

Mass Production

Facilities in Qingdao and Dongying with a combined monthly output of 1.3 million pieces.

Global Reach

Exporting to over 40 countries, meeting international marine engineering standards.

VastPCC Marine Engineering Product Series

Explore our premium Stainless Steel High-Temperature Alloys and Carbon Steel Castings, engineered for critical marine systems including vessels, offshore platforms, pumps, and valves. Precision-crafted to meet the highest standards of durability and performance.

Stainless Steel High-Temperature Alloys

Our stainless steel alloys withstand extreme temperatures and corrosive marine environments, ensuring longevity and safety in offshore platforms and vessels.

- High corrosion resistance

- Exceptional thermal stability

- Ideal for pumps, valves, and critical components

Carbon Steel Castings

Robust carbon steel castings designed for structural integrity and reliability in harsh marine conditions, perfect for vessels, pumps, and valves.

- Superior mechanical strength

- Precision casting for complex shapes

- Wide application in marine critical systems

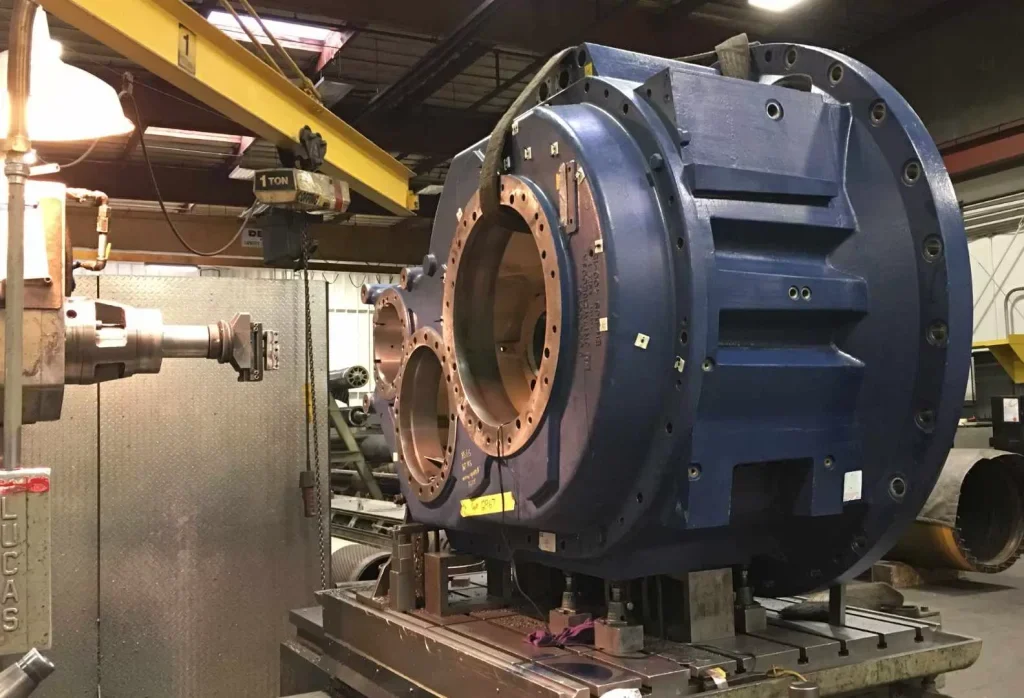

Finished Products & Precision Processing

Advanced Technology Ensuring Quality and Durability

Silica Sol Precision Casting Technology

Discover the superior benefits of silica sol precision casting technology, delivering unmatched quality and durability for critical applications.

Strategic R&D Collaborations

Partnering with China Metallurgical Research Institute and Xi’an Aero Engine Corporation, VastPCC drives innovation through cutting-edge research and development.

Continuous Innovation & Quality Control

Rigorous quality control systems and ongoing innovation guarantee consistent performance and reliability in every product.

Learn More

Successful Projects & Client Testimonials

Flagship Marine Engineering Projects

VastPCC has delivered customized marine engineering solutions across diverse industries including shipping, offshore energy, and port infrastructure. Our projects tackled complex challenges such as corrosion resistance, structural durability, and integration with legacy systems.

Outcomes consistently exceeded expectations, enhancing vessel lifespan and operational efficiency through innovative materials and precision engineering tailored to each client’s unique technical requirements.

- Enhanced durability with corrosion-resistant alloys

- Custom solutions for complex marine environments

- Seamless integration with existing infrastructure

Client Testimonials

“VastPCC’s marine components have proven incredibly reliable in harsh offshore conditions. Their team’s expertise and responsiveness made all the difference in meeting our project deadlines and quality standards.”

“The customized solutions VastPCC provided allowed us to extend the service life of our fleet significantly. Their commitment to service excellence and technical precision is unmatched.”