Precision Casting Solutions for Extreme Environments

VastPCC delivers cutting-edge high-temperature alloys and investment casting technology engineered for oil, gas, and industrial applications.

Industry Overview - Oil & Gas Chemical Challenges

The oil and gas chemical industry faces complex challenges including corrosion resistance, material durability, and environmental compliance. VastPCC leverages deep expertise to provide advanced material solutions tailored to these demanding conditions.

- Corrosion-resistant alloys and coatings

- High-performance casting and fabrication

- Compliance with stringent safety and environmental standards

- Innovative chemical processing materials

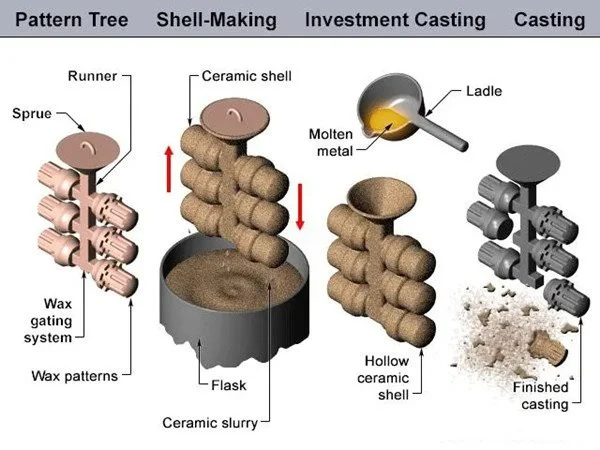

Advanced Casting

Precision investment casting ensures components meet exacting standards for strength and reliability in harsh chemical environments.

Automation & Quality

Cutting-edge robotics and automation improve quality control and production efficiency for VastPCC’s chemical industry solutions.

Material Testing

Rigorous testing protocols ensure materials withstand extreme conditions, extending asset life and reducing downtime.

VastPCC Core Products & Solutions

Precision Casting Product Categories

VastPCC specializes in high-precision casting solutions tailored to your exact specifications. Our product categories cover a wide range of applications, ensuring superior quality and performance.

- Customizable casting designs for complex geometries

- Corrosion-resistant alloys for extended durability

- High-stress performance materials engineered for reliability

- Advanced metallurgy for enhanced mechanical properties

Corrosion Resistance

Our corrosion-resistant castings ensure longevity in harsh environments, reducing maintenance costs and downtime.

High Stress Performance

Engineered for demanding applications, our castings withstand extreme mechanical stresses without compromising integrity.

Customization

Tailor-made casting solutions to meet your exact specifications, ensuring optimal fit and function for your projects.

Technology & Process Advantages

Silica Sol Precision Casting

VastPCC leverages advanced silica sol precision casting techniques to achieve unparalleled surface finish and dimensional accuracy. This process ensures superior mold stability and fine detail reproduction for complex components.

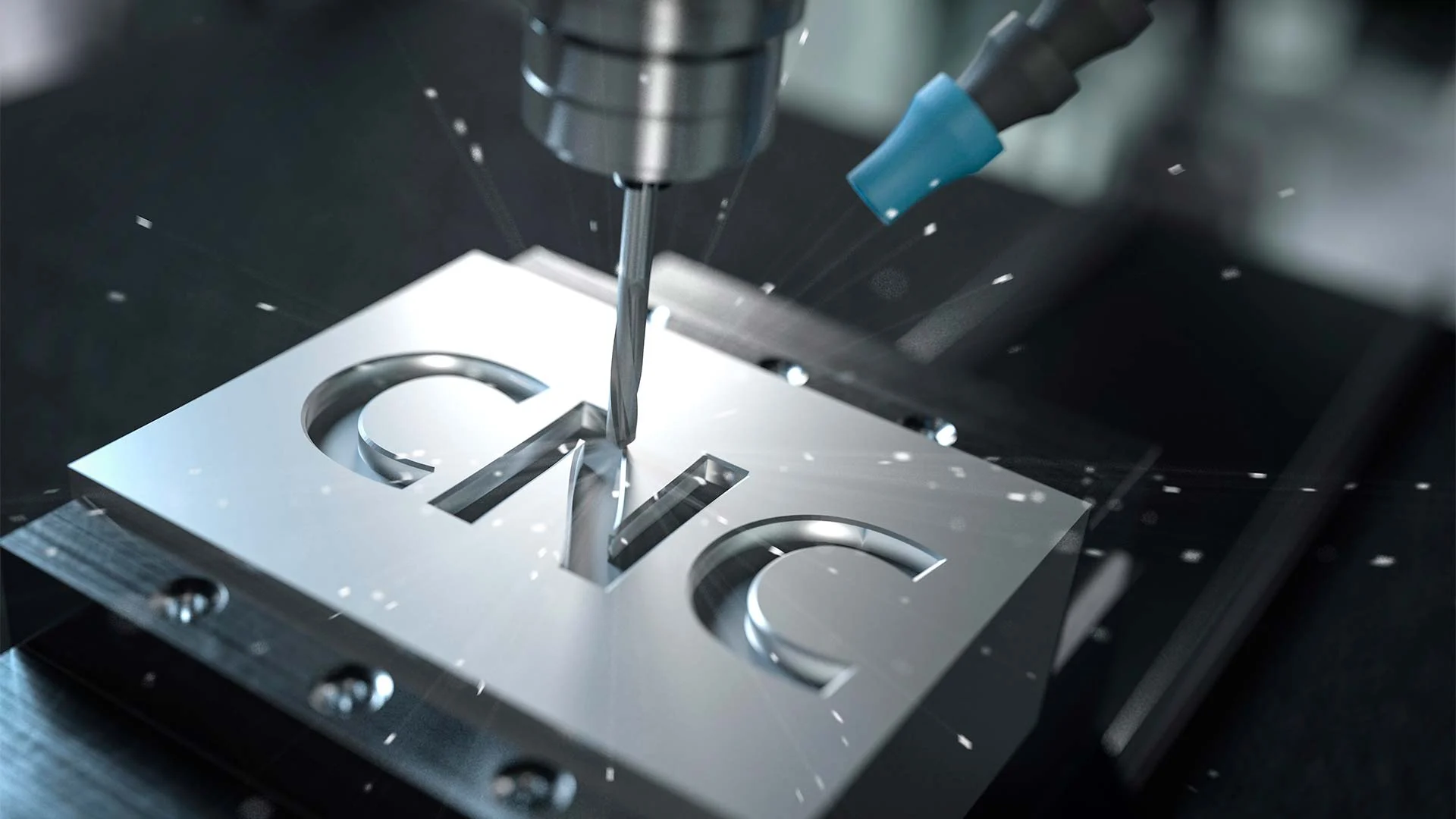

Surface Treatment & Machining

Our integrated surface treatment and precision machining workflows guarantee enhanced durability and tight tolerances. This collaboration between processes reduces lead times and improves overall product quality.

Innovation & Collaboration

At VastPCC, innovation drives every step. Our cross-disciplinary teams work closely to optimize materials, processes, and design — delivering cutting-edge solutions that meet evolving industry demands.

Learn More

Application Cases & Customer Feedback

Chemical Industry Casting Solutions

VastPCC’s stainless steel casting technology has revolutionized chemical processing plants by delivering corrosion-resistant, durable components that withstand harsh environments.

Customer Testimonials

“VastPCC’s precision casting and automation have significantly improved our production efficiency and product quality.” – John D., Manufacturing Manager

Quality Control & Certification Module

Ensuring international quality management standards, production capacity, and compliance certifications for your peace of mind.

International Certifications

VastPCC adheres to globally recognized quality standards including ISO 9001, ensuring your products meet rigorous compliance requirements.

Production Capacity

Our advanced manufacturing facilities guarantee high-volume production without compromising quality or delivery timelines.

Standards Compliance

Compliance with industry-specific standards ensures your products are safe, reliable, and ready for global markets.